Scraper Filter Fully Automatic Control Systems

Core Components Of The System

1. Scraper drive motor, differential pressure controller, differential pressure switch, indicator light, valve alarm system timer or display optional.

2. Overload protection circuit breaker.

3. PLC-based control system with adjustable timers for scraper and blowdown opera.

4. Differential pressure controller protection and monitoring system.

5. Drain valve drive: electric/pneum atic.

6. Pre-assemble and tested installstion.

Control Options

A. 120V 230V 380V 400V 460V 480V 575V 1PH or 3PH 50 or 60Hz

B. Electricpower system: Customer-customized integrated local control system or advanced personalized requirements

C. Optional: local/remote control, switch, timer, touch screen control system

D. Remote supervision: dry contacts, PLC based, 4-20mA, audible alarms, DH-485, digital/analog

Self-cleaning Scraper-strainer

|

Model No.

|

S2-273

|

S2-325

|

S2-426

|

S2-530

|

S2-630

|

S2-720

|

S2-820

|

S2-920

|

S2-1020

|

|

Pipe diameter(mm)

|

80

|

100

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

|

Flow rate(m³h)

|

50

|

150

|

300

|

500

|

700

|

1100

|

1500

|

2000

|

2500

|

|

Filter area(㎡)

|

0.25

|

0.35

|

0.66

|

1.0

|

1.2

|

1.5

|

1.8

|

2

|

2.3

|

|

Drain valve DN(mm)

|

25

|

25

|

50

|

50

|

80

|

80

|

80

|

80

|

80

|

|

Clean water consumption (one time)(L)

|

80

|

80

|

150

|

150

|

350

|

450

|

600

|

800

|

1000

|

|

Motor power (KW)

|

0.55

|

0.55

|

0.55

|

0.55

|

0.75

|

0.75

|

0.75

|

0.75

|

0.75

|

|

Model No.

|

D(mm)

|

H1(mm)

|

H2(mm)

|

H3(mm)

|

H4(mm)

|

L1(mm)

|

L2(mm)

|

L3(mm)

|

|

S2-273

|

273

|

950

|

620

|

150

|

1450

|

236.5

|

236.5

|

180

|

|

S2-325

|

325

|

1070

|

620

|

150

|

1600

|

282.5

|

282.5

|

200

|

|

S2-426

|

426

|

1275

|

785

|

150

|

1870

|

343

|

343

|

250

|

|

S2-530

|

530

|

1445

|

845

|

150

|

2200

|

415

|

415

|

300

|

|

S2-630

|

630

|

1600

|

1000

|

200

|

2455

|

465

|

465

|

350

|

|

S2-720

|

720

|

1620

|

1020

|

200

|

2550

|

510

|

510

|

400

|

|

S2-820

|

820

|

1735

|

1035

|

200

|

2700

|

610

|

610

|

450

|

|

S2-920

|

920

|

1825

|

1125

|

200

|

2800

|

660

|

660

|

500

|

|

S2-1020

|

1020

|

1850

|

1200

|

200

|

2960

|

710

|

710

|

550

|

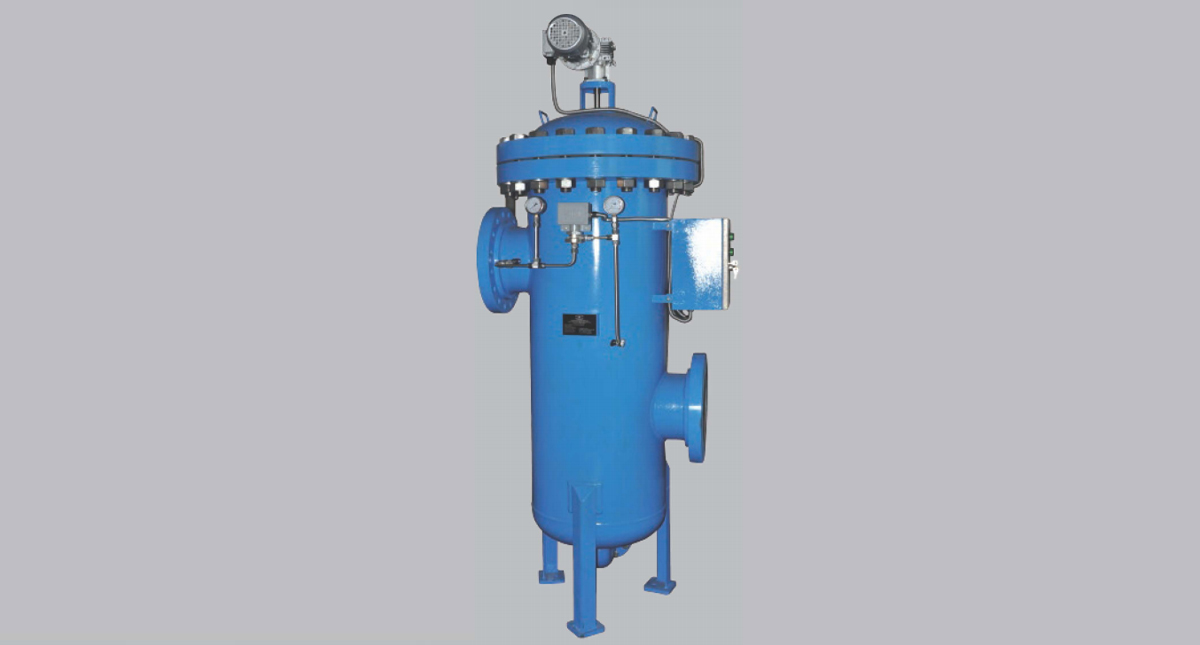

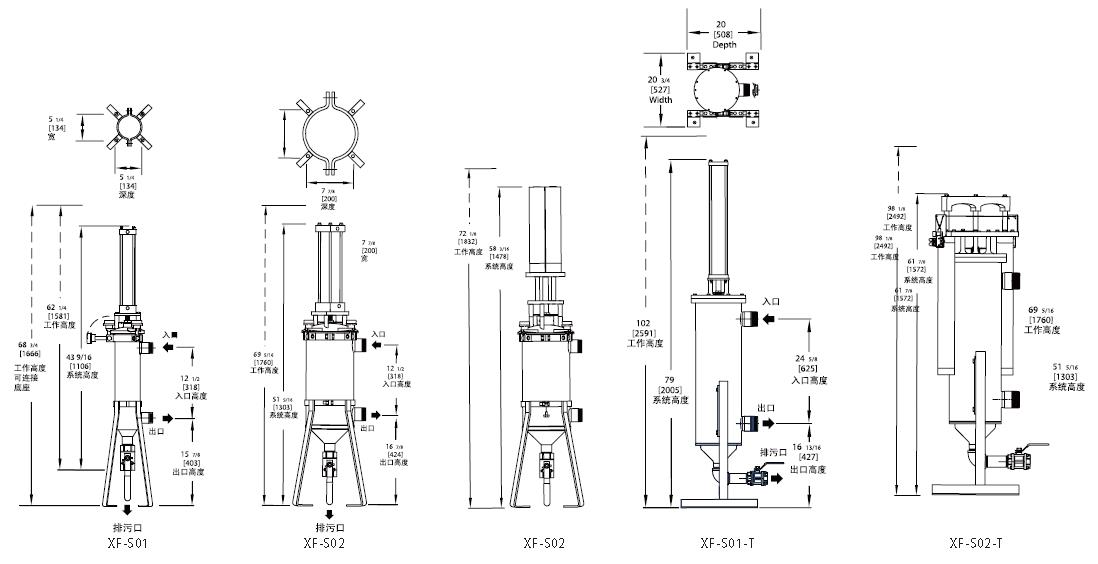

YNTSH-XF-S SERIES

Cylinder scraper automatic self-cleaning filter series

XF-S series cylinder scraper automatic self-cleaning filter is the ideal choice for filtering high viscosity, high corrosion resistance, and high pressure liquid.

XF-S series scraper filter is self-development by Inoco, this new generation of mechanical self-cleaning filter has reached the world advanced technology level. Different with backwashing self-cleaning water filter, scraper filter is not only used for water filtration, but also widely used in the self-cleaning filtering of solvents, acid alkali, polymer, coating adhesive materials and so on, it has higher efficiency and precision of range 30-1500 microns. It can filter liquid viscosity up to 800000 centipoises, and also be applied in water treatment, petrochemical, metallurgy, electric power, chemical, paint, printing ink, paper, food and beverage, pharmaceutical, metal processing industries and etc.

XF-S series scraper filter which is fully automatic operation, high filtration precision, stable and reliable performance is an efficiency choice of replacing traditional manual filter or use dumping type material filter. In many areas it can replace the traditional cartridge filters, bag filters, basket filters, vibrating screen filters.

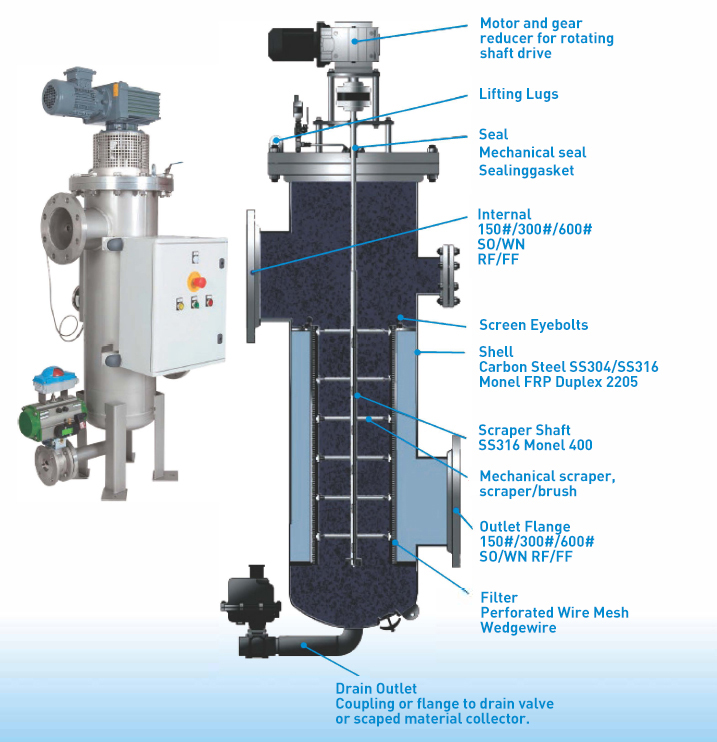

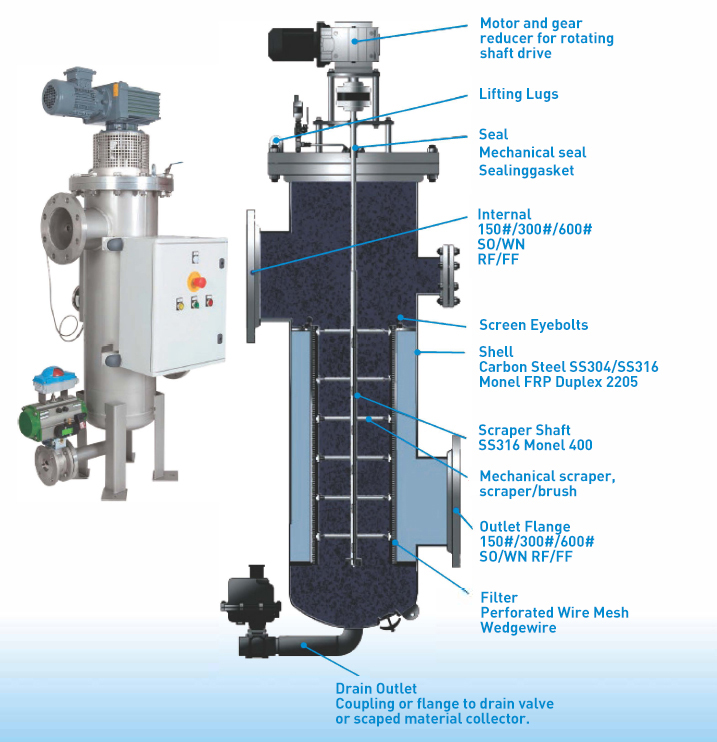

Parts Material

Filter body: CS/SS304/SS316L isresistant toacidand alkali solution corrosionand has better performance.

Mesh: SS304/SS316L

Drive Shaft seal: PTFE Teflon,suitable for all kinds of solvent, acidicand alkaline liquid, maximumoperating temperature 230℃.

Sealing ring: NBR acrylic rubber, applicable to most of the neutral and oily liquid, maximumoperating temperature 120℃.

VITON fluorine rubber: Resistant to acidic and alkaline liquid and the majority of the solvent, maximumoperating temperature 230℃.

Scraper: SF type is super wear resistant synthetic material, SS type is Wear resistant stainless steel scraper.

Support foot: SS304

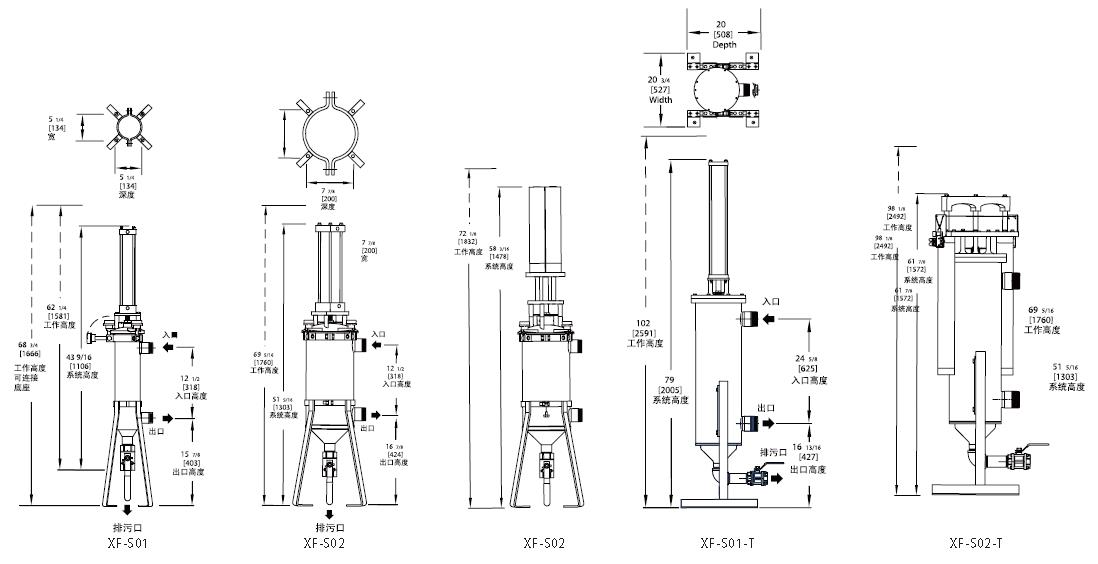

XF-S SERIES

Technical Parameters

Model Selection Reference

|

Model

|

XF-S01

|

XF-S01-T

|

XF-S02

|

|

Weight

|

35 Ibs (16kg)

|

75 Ibs (34kg)

|

215 Ibs (97.5kg)

|

|

Working height

|

61.25 in (1556 mm)

|

69.25 in (1760 mm)

|

102 in (2591 mm)

|

|

Total capacity

|

0.94 gal (3.5 liters)

|

3.9 gal (14.8 liters)

|

11 gal (41.6 liters)

|

|

Drain chamber capacity

|

4 fl.oz (119ml)

|

25 fl.oz (0.74liters)

|

1.5 gal (6 liters)

|

|

Filtration area

|

112in² 722cm²

|

264in² 1703cm²

|

610in² 3935cm²

|

|

Flow rate range

|

2-20 gpm/0.45-4.5m³/hr

|

20-60 gpm/4.5-13.6m³/hr

|

60-200 gpm/13.6-45.4m³/hr

|

|

Max temperature

|

350° F(177°C)

|

350° F(177°C)

|

350° F(177°C)

|

|

Max pressure

|

300 psi(21 bar)

|

150 psi(10.5 bar) standard

|

150 psi(10.5 bar) standard

|

|

Air driver needs

|

400/800=60 psi at 5 cfm (4 bar@8.5m³/min) 1600=80 psi at 5 cfm (5 bar@8.5m³/min)

|

|

Control power

|

available for the three type,limit to automatic 110/220v,50/60 HZ single

|

YNTSH-XF-S3 SERIES

Outer-scraper automatic self-cleaning filter series

XF-S3 series out-scraper self-cleaning filter is designed specifically for paper making industry, solving the problem of coating and pulp filtering. It can remove broken paper and streaks and reduce the emissions impact to environment, and make sure the work time and product quality in greatest extent.

XF-S3 SERIES

Technical Parameters

Automatic cleaning filter mesh

It uses the speed reducer to drive the cyclotron scraper and clean the dirt attached on the mesh to keep the cartridge filtration function. The unique clear design keeps flowing unblocked forever. Precision scraper pressure and angle design ensure zero damage to mesh in a short time and it is

durable and can be changed quickly.

Wedge filter screen working pressure option

Wedge filter screen 1mm

Suitable for Working pressure lower than 16kg/cm²

Wedge filter screen 1.5mm

Suitable for Working pressure lower than 16-30kg/cm²

Wedge filter screen 1.8mm

Suitable for Working pressure higher than 30kg/cm²

(standard for Φ85mm)

Standard size

A: OD, 85, 168, 268.

L: Standard filter mesh length is 600mm.

INOCO Green Energy Solutions Co., Ltd. |