▍INOCO SGF Series Liquid - Liquid Separation Filter

Generally used in the separation of water in gasoline, jet fuel, and diesel

Separation of caustic in gasoline, jet fuel, and diesel

Separation of water in light hydrocarbons and petrochemicals

Separation of hydrogen peroxide in working mother liquor

Separation of acids in petrochemicals and hydrocarbons

Separation of oil in water

Separation of oil in anhydrous amines

SGF Oil Water Separator

A coalescing filter element and a separation filter element areinstalled in the oil-water separation filter housing.

The mass flow through its interior needs to go through fourprocesses: filtration,coalescence, sedimentation, and separation Thus realize the removal of water, lye, and water-solubleorganic acid salts in the medium.

The media first flows from the inside to the outside through thecoalescing filter element, which has a special filter.

Coalescing filter element has the dual function of filtering andcoalescing moisture.The inner layer of the coalescent filterelement is a high-precision filterlayer, which can effectively intercept the particle impurities inthe medium, especially for the stable emulsification state ofiron oxide, iron sulfide, and otherimpurities, conducive to subsequent demulsification andcoalescence function. The filtered media then enters thedemulsification coalescing layer of the coalescing filter element.

The special material in the demulsification coalescinglayer demulsifies the medium, tiny, free water coalesces outand condenses into water droplets on itssurface. Large water droplets settle into the collectingtank by their own gravity, and smaller water dropletsflow with the medium to the separation filterelement. The separation filter element is made ofpatented technical material, with good hydrophobicity,when the medium flows through the separation filterelement from outside to inside, only let the medium flowthrough, the small water droplets are completely andeffectively intercepted outside the filterelement, and coalesce into large water beads to furtherseparate out the moisture.

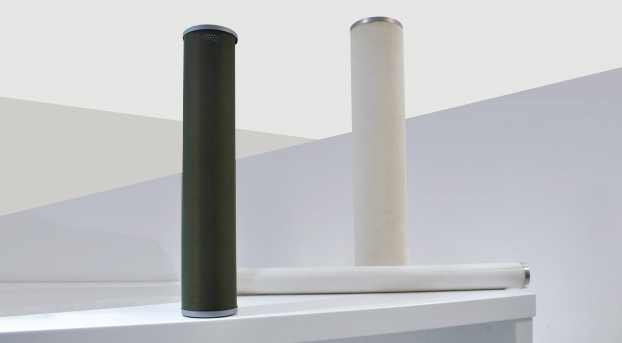

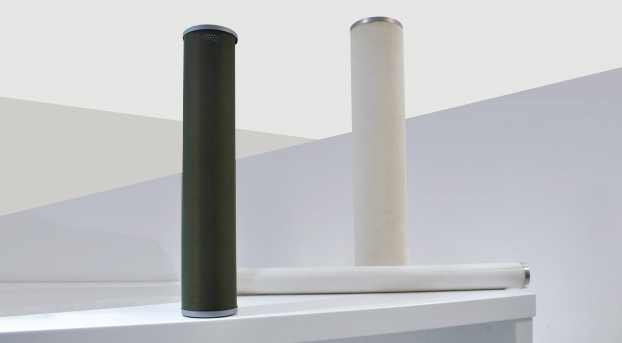

▍INOCO Filter Cartridge Media

Coalescing Separation Filter

The coalescent filter element mainly selects glass fiber or polyester fiber after surface treatment as coalescent medium.

The structure of the filter material is specially designed to make the filter medium have good coalescence performance.

The filtrationaccuracy can reach 0.1 m.

Separation Filter Element

The separation filter element is made of high-density gradient glass fiber, which is designed as a monolithic tube structure to reduce damage and leakage.The surface of the filter element is treated with hydrophobic and oil-phobic, which can meet the requirements of various precision grades.

Filter Data

Filter housing material:

20#、Q345R、SS

Accuracy range:

less than 0.3m、0.3m、0.5m、1m、5m、10m

Filter element size:

O.D3.5''、4.5''、6''

Length16、18、20、32、36、40、72

Initial differential pressure:≤50bar

Differential pressure:<150Bar

Operating temperature:0~120℃

Structure

Liquid-liquid coalecating separator is a metal shell equipped with two groups of filter elements with different functions inside, and with outside accessories such as liquid level gauge, differential pressure gauge, vent valve, drain (discharge) valve and online sampling joint.

Process Flow

● In order to prolong the service life of coalescence filter element in coalescence separator and improve the dehydration efficiency, it is recommended to install a pre-filter before coalescence separator. The purpose of the pre-filter is mainly used to filter out the larger solid particle impurities and harmful impurities such as iron oxide and iron sulfide in the medium.

● Each device is designed with bypass, easy to replace the filter element, to ensure the continuous operation of the system.

● Every sewage outlet at the bottom of the device are designed, is conducive to recycling sewage discharge and isolated from the media.

|

Model

|

Inlet/Outlet

Size

|

Flow t/h

|

Coalescing Element

|

Separation Element

|

D

|

H1

|

H2

|

H3

|

Maintenance

Space

|

|

SGF-15

|

80

|

15

|

φ150×500(2)

|

φ150×500(1)

|

450

|

257

|

1264

|

1441

|

600

|

|

SGF-45

|

100

|

45

|

φ150×500(4)

|

φ150×500(2)

|

600

|

337

|

1447

|

1679

|

600

|

|

SGF-75

|

100

|

75

|

φ100×500(12)

|

φ100×500(6)

|

700

|

320

|

1451

|

1698

|

600

|

|

SGF-90

|

150

|

90

|

φ150×500(8)

|

φ150×500(4)

|

800

|

346

|

1550

|

1834

|

600

|

|

SGF-60

|

100

|

60

|

φ100×400(12)

|

φ150×400(6)

|

800

|

331

|

1400

|

1684

|

600

|

|

SGF-270

|

200

|

270

|

φ150×1120(11)

|

φ150×1120(5)

|

900

|

345

|

2315

|

2631

|

1200

|

|

SGF-180

|

200

|

180

|

φ150×710(12)

|

φ150×710(5)

|

900

|

345

|

1905

|

2221

|

800

|

|

SGF-300

|

250

|

300

|

φ150×710(20)

|

φ150×710(8)

|

1100

|

394

|

2062

|

2435

|

800

|

▍INOCO SGD SMagn etic Filter

Product Description

Fluid pipe iron remover, also called magnetic fluid iron remover or magnetic fluid filter, is applied in fluid, semi-fluid and other fluid materials with different viscosities to remove iron impurities and other ferromagnetic particles, so that the materials can be kept clean, and at the same time, it also plays a role in protecting the downstream production equipment.

Product Features

◎ A number of different types of fluid separators have been developed to suit a wide range of different conditions of use.

◎ Magnetic force can be selected from the same range as the magnetic frame, up to 12000GS for normal style (Nstyle) and 8000GS for easy cleaning style (Estyle).

◎ Standard working temperature ≤80℃, under special requirements, the maximum working temperature can reach 350℃ .

◎ Easily install, remove and clean magnetic components using designs such as flanges, clamps, bolt plates or quick-release cleats.

◎ Piping materials are available in 304 or 316L stainless steel.

◎ Reasonable structural design ensures the best iron removal effect without hindering the flow of materials.

◎ Pressure usage requirements or other special requirements are available upon request.

▍INOCO SGDZ Double cylinder filter

Working Principle

Double-cylinder filter, also known as double-cylinder return pipeline filter, is composed of two single-cylinder filters and a two-position six-way reversing valve, with simple structure, easy to use, and with a bypass valve and filter element contamination clogging sender to ensure system safety.

In the working process, when the single cartridge filter element is clogged to a certain extent and needs to be cleaned or replaced, the host has to be stopped to replace the filter element, which not only wastes time but also fails to meet the host's needs for continuous work, and the doublecartridge filter effectively solves the shortcomings of the single-cartridge filter in this regard, and can be used for cleaning or replacing the cartridge without stopping to ensure the host's normal continuous work.

When a filter element is clogged and needs to be replaced, it is not necessary to stop the work of the host, just open the pressure balance valve and turn the reversing valve, another filter can participate in the work, and then replace the clogged filter element.

Uses and Application

It is mainly applied to the filtration of fuel oil and lubricating oil of marine diesel engine, chemical equipment, power generation equipment hydraulic and lubrication system, filtering out the dirt which is not dissolved in the oil, in order to maintain the cleanliness of the oil.

Technical Data

Max working temperature : not greater than 95℃.

Max working pressure:1.0Mpa、1.6Mpa、2.5Mpa、4.0Mpa.

Cartridge cleaning pressure drop not greater than 0.15Mpa-0.35Mpa.

INOCO Green Energy Solutions Co., Ltd. |