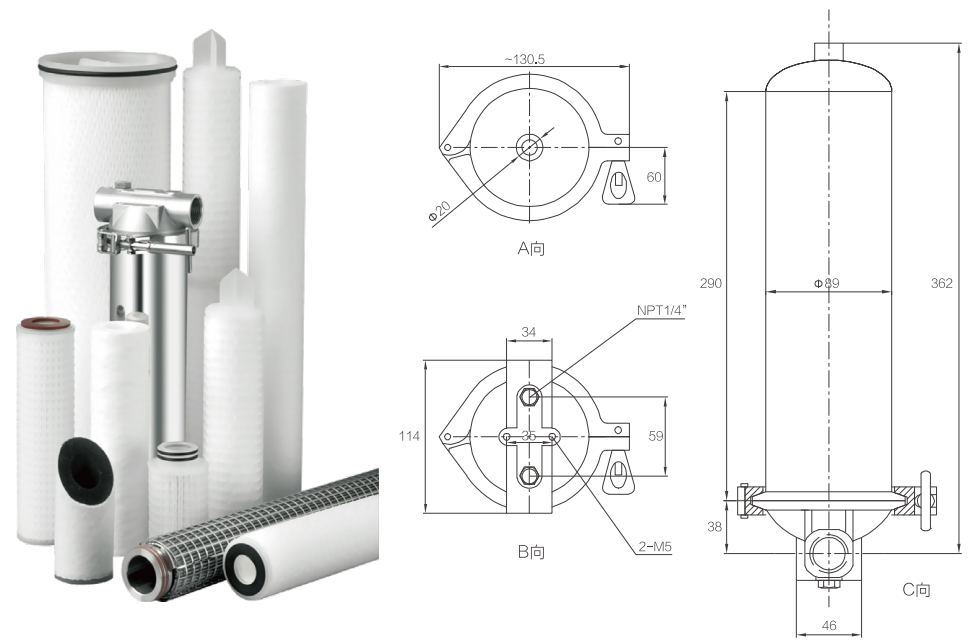

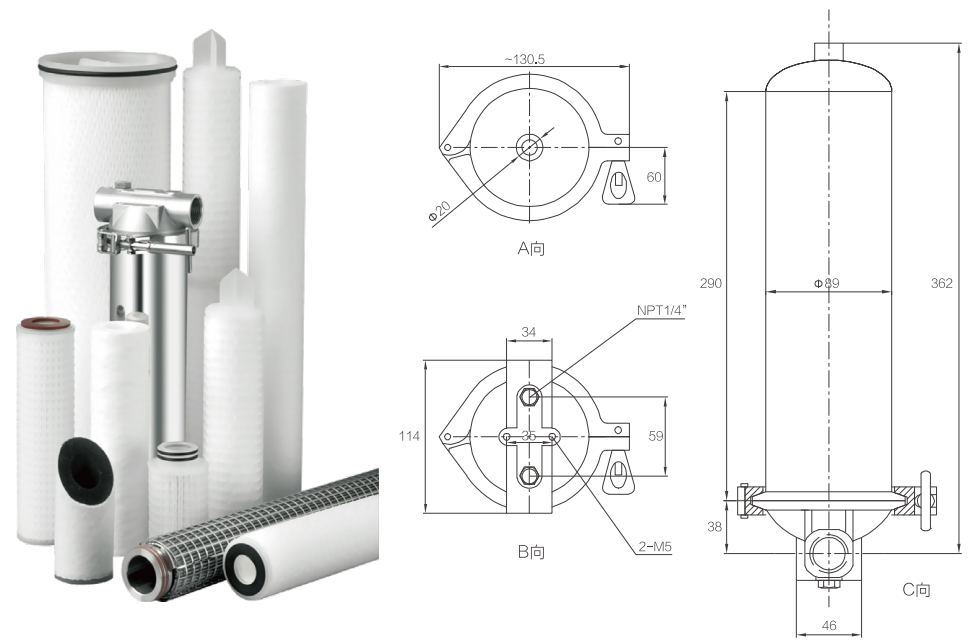

▍INOCO SCG - C Series Casting Filter

INOCO SCG-C series casting single-core filter consists of three main parts, silica-sol casting filter head, filter barrel, and filter cartridge. The filter is easy to dismantle and maintain; the filter is suitable for installing 10″~20″ size filter cartridges, including those made of solvent injection, glass fiber and other materials. The top of the filter is equipped with NPT3/4″ inlet and outlet.

Filter Selection Guide

Filter Selection Guide

|

Model

|

Filter Element Size

|

Flow Rate

|

Dimensions

|

L

|

|

SCG-C-I

|

10"

|

1.5T/H

|

65-250

|

362

|

|

SCG-C-II

|

20"

|

3T/H

|

65-500

|

612

|

Filter Materials

|

Filter Component

|

Material

|

|

Housing

|

WCB、304、316L

|

|

Filter Element

|

Foam spray, fiberglass, polypropylene, PTFE, stainless steel, etc.

|

|

Housing Gasket

|

Nitrile (standard) Optional: EPDM, fluoroelastomer, PTFE-coated rubber

|

|

Filter Element Gasket

|

EPDM, fluoroelastomer

|

Filter Performance Parameters

|

Filtration Precision

|

0.003micron~100micron

|

|

Design Temperature

|

80℃

|

|

Design Pressure

|

1.0Mpa

|

|

Single Filter Element Flow Rate

|

Maximum 5T/H(depends on precision and cartridge)

|

SCG-C Series Filter Performance Features

◎ No need to dismantle piping when using glass filter cartridges

◎ Easy disassembly, low maintenance cost

◎ Filter uses closed structure, low cost, rational design

◎ Suitable for mass production

◎ Filter cartridge uses double-open design, fixed at both ends

▍INOCO SCG-H Series Single Cartridge High Pressure Filter

INOCO SCG-H series filters are equipped with one stainless steel cartridge, such as stainless steel folded, stainless steel sintered, (the length can be selected from 5 to 40 inches) of different specifications, and different flow rates can be achieved depending on the material, pore size and length. The design of sanitary structure can be applied to pharmaceutical, food and beverage and other special industries. The cartridge connection form of the filter generally adopts 222 or threaded form. Pressure gauge can be optional ordinary pressure gauge or diaphragm pressure gauge. Each unit undergoes strict pressure test inspection before leaving the factory.

Filter Materials

|

Filter Component

|

Material

|

|

Housing

|

20# II、304 II、316 II

|

|

Filter Element

|

Stainless steel wire mesh, stainless steel pleated, non-metallic material + stainless steel frame

|

|

Housing Gasket

|

Fluoroelastomer (standard), optional EPDM, PTFE-coated rubber

|

|

Fitter Element Gasket

|

Fluoroelastomer

|

Filter Performance Parameters

|

Filtration Precision

|

0.003micron~100micron

|

|

Working Temperature

|

80℃ (standard), special cases up to 450℃ depending mainly on filter element

|

|

Working Pressure

|

6.3Mpa (standard),42Mpa (H specification)

|

▍INOCO SCG-W Series Welding - Single Filter Element Filters

▍INOCO SCG-W Series Welding - Single Filter Element Filters

INOCO SCG-W series filters can be equipped with one microporous cartridge (length optional 5~40 inches) of different specifications, which can achieve different flow rates depending on the material, pore size and length. The design of sanitary structure can be applied to pharmaceutical, food and beverage and other special industries. Filter and cartridge connection form generally adopts 226, 222 or threaded form. Pressure gauge can be optional ordinary pressure gauge or diaphragm pressure gauge. Each unit undergoes strict pressure test inspection before leaving the factory.

Filter Materials

|

Filter Component

|

Material

|

|

Housing

|

20#, 304, 316L, 2205, Alloy, PP-lined, PTFE-coated

|

|

Filter Element

|

Foam spray, fiberglass, polypropylene, PTFE, stainless steel, etc.

|

|

Housing Gasket

|

Nitrile (standard), optional EPDM, fluoroelastomer, PTFE-coated rubber

|

|

Filter Element Gasket

|

EPDM, fluoroelastomer

|

Filter Performance Parameters

|

Filtration Precision

|

0.003micron~100micron

|

|

Design Temperature

|

80°C / Special design required for over 80°℃

|

|

Design Pressure

|

1.0Mpa / Special design required for over 1.0Mpa

|

|

Flow Rate

|

Maximum 5T/H depending on precision and filter element

|

Filter Dimensions

|

Model

|

Filter Element Size

|

Filter Element Dimensions

|

Housing Dimensions

|

Inlet/Outlet

|

Vent

|

Drain Port

|

|

SCG-W-I

|

10"

|

65-250

|

102×520

|

1"

|

1/2"

|

1/2"

|

|

SCG-W-II

|

20"

|

65-500

|

102×760

|

1"

|

1/2

|

1/2"

|

|

SCG-W-III

|

30"

|

65-750

|

102×1000

|

1"

|

1/2"

|

1/2"

|

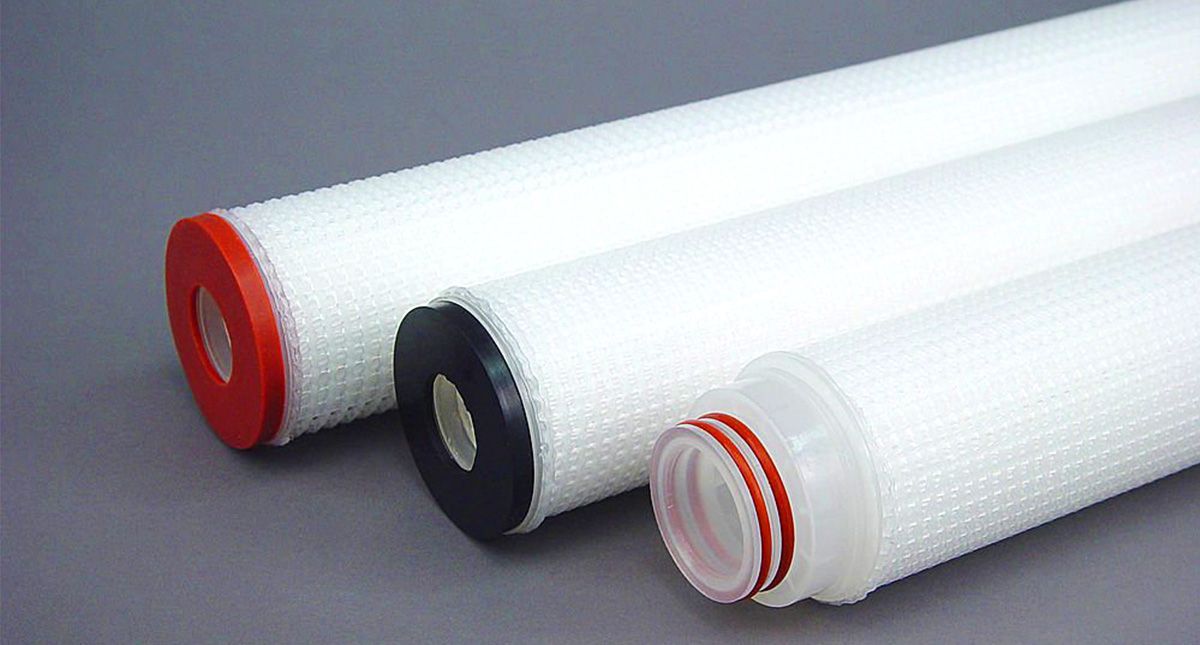

CARTRIDGE FILTER

INOCO Filter Membrane's precision quality control process, from the precise blending of raw materials to the precise control of the pore size of the membrane, enables the product to meet the stringent requirements of our customers in different applications. We hope to ensure that each in-line product fully realizes its design specifications through our perfect design, lean manufacturing, and efficient after-sales service.

Filter Description

The filter applies reasonable fluid mechanics technology, and can be designed, manufactured and accepted in accordance with ASME “U”, GB150-1998 “HG532-91 Chemical Pipeline Filter”. Innotek welded filters have more than 1900 forms to choose from, and have the experience of providing programs for more than 18,000 enterprises.

Type Reference

High-Pressure Type:42Mpa | High-Temperature Type:1000℃ | Special Material Type:Duplex Steel, Hastelloy, PTFE-Lined

Filter Cartridge Applications

▍Melt-blown filter cartridge

The most economical filter cartridge

▍Pleated polypropylene filter cartridge

Suitable for process water pre-filtration

▍Non-fiber shedding polypropylene filter cartridge

Applied to occasions with high requirements for fiber shedding

▍High dirt-holding capacity polypropylene filter cartridge

Suitable for high solid content conditions, more than 3 times that of ordinary polypropylene filter cartridges

▍PTFE Pleated Filter Cartridge

Absolute precision filtration for pure water

▍Asymmetric PTFE Filter Cartridge

Ultra-long life absolute precision filter cartridge

▍PTFE Pleated Filter Cartridge

Absolute precision filtration for various acidic liquids

▍PPS Frame with PTFE Membrane Filter Cartridge

Absolute precision filter cartridge for 120°C liquid filtration

▍PVDF Membrane Filter Cartridge

Acid and alkali resistant absolute precision filter cartridge

▍High Flow Polypropylene Filter Cartridge

Suitable for high flow and high contamination filtration

▍Stainless Steel Pleated Wire (Mesh) Filter Cartridge

Suitable for high flow, high temperature and high pressure working conditions

▍316L Powder Sintered Filter Cartridge

Suitable for self-cleaning absolute precision filtration

▍Glass Fiber Liquid Filter Cartridge

Especially suitable for liquid glue filtration

Most Heat-Resistant Filter Cartridge

▍Glass Fiber Filter Cartridge+ Replaceable Steel-lined PTFE Frame

Ultra-high strength corrosion-resistant filter cartridge

▍INOCO-MSO-S Series Multi-cartridge Filter

▍INOCO-MSO-S Series Multi-cartridge Filter

With many years of R&D experience and technology accumulation in membrane

manufacturing process, INOCO adopts the most advanced technology and production

equipment to provide all kinds of high-efficiency and high-quality micro-porous

membrane filtration systems for customers all over the world. Applying reasonable

fluid mechanics technology, the filters can be designed, manufactured and accepted in

accordance with the design, manufacturing and acceptance standards:

steel pressure vessels, water treatment filter standards, ASME “U” stamp design,

manufacturing and acceptance.

Filter coneect size:

DN15-DN500 or NPT、Standard thread

Drain:DN15~DN50 | Vent:DN15

Surface Finishing:Mechanical polishing, electrolytic polishing, sand blasting, painting.

Safe operating temperatures and pressures will depend on the cartridge and sealing.

Please specify pressures and temperatures greater than those mentioned above.

Filter Material

|

Filte Item

|

Material

|

|

Shell

|

20#、304、316L、2205、Alloy, PP lining, sprayed PTFE

|

|

Element

|

Meltblown,glassfibe, polypropyle, PTFE tainlessteel etc.

|

|

Body gasket N

|

NBR (standard] optional : EPDM, Viton, PTFE-coated vition

|

|

Element gasket

|

EPDM, Viton

|

Filter Performance Parameters

|

Filtration Acuracy

|

0.003 m~100 m

|

|

Design Temp.

|

80℃ / >80C Requires special design

|

|

Design Pressure

|

1.0Mpa/ >1.0Mpa Requires special design

|

|

Design Flow

|

0.1-500m/h-Depends on accuracyand element

|

|

Element Q'ty

|

3-300pcs

|

|

Element Lenght

|

250、500、750、1000mm

|

|

Model

|

Element size

|

Inlet/outlet

|

H1

|

H2

|

H3

|

H4

|

L

|

D

|

t1

|

Flow

|

|

MSO-S-3-30

|

3pcs*30"

|

DN50

|

200

|

373

|

1189

|

860

|

420

|

Φ219

|

3

|

3T/H

|

|

MSO-S-7-30

|

7pcs*30"

|

DN50

|

200

|

438

|

1250

|

860

|

506

|

Φ300

|

3

|

7T/H

|

|

MSO-S-12-30

|

12pcs*30"

|

DN65

|

200

|

469

|

1287

|

870

|

556

|

Φ350

|

3

|

12T/H

|

|

MSO-S-15-40

|

15pcs*40"

|

DN80

|

200

|

486

|

1558

|

1120

|

606

|

Φ400

|

4

|

23T/H

|

|

MSO-S-19-40

|

19pcs*40"

|

DN80

|

250

|

579

|

1659

|

1130

|

698

|

Φ450

|

4

|

29T/H

|

|

MSO-S-26-40

|

26pcs*40"

|

DN100

|

250

|

592

|

1683

|

1140

|

750

|

Φ500

|

5

|

39T/H

|

|

MSO-S-32-40

|

32pcs*40"

|

DN100

|

300

|

652

|

1747

|

1140

|

800

|

Φ550

|

5

|

48T/H

|

|

MSO-S-38-40

|

38pcs*40"

|

DN125

|

300

|

687

|

1799

|

1160

|

850

|

Φ600

|

5

|

57T/H

|

|

MSO-S-45-40

|

45pcs*40"

|

DN125

|

300

|

701

|

1824

|

1170

|

902

|

Φ650

|

6

|

68T/H

|

|

MSO-S-54-40

|

54pcs*40"

|

DN125

|

300

|

715

|

1844

|

1170

|

952

|

Φ700

|

6

|

81T/H

|

Note: 1, t2 ≥ 16; 2, the above flow accuracy in 10 microns, different conditions of different flows, for reference only.

▍INOCO MSO-DS Multi-Cartridge Filter Series

INOCO multi-cartridge filter is a multi-functional filter, which consists of filter shell and filter element. It has been widely used for

solid-liquid separation in petroleum, chemical, machinery, metallurgy, textile, printing and dyeing, electroplating, medicine, food and other

industries. The filtered liquid is pressed in by the inlet of the filter, and is filtered into clear liquid through the filter layer from the outside

to the inside of the filter element, and then discharged through the outlet. The impurities are retained in the deep layer and surface of the

filter element, so that the liquid is filtered for the purpose.

Filter Size

Filter Material Filter Performance Parameters

Filter coneect size:DN15-DN500 or NPT、Standard thread

Drain:DN15~DN50 | Vent:DN15

Surface Finishing:Mechanical polishing, electrolytic polishing, sand blasting, painting

● Safe operating temperatures and pressures will depend on the cartridge and seals, please note that pressures and temperatures greater than those mentioned above are not recommended.

● Design, manufacture and acceptance standards: < GB150-1998> steel pressure vessels, water treatment filter standards, ASME 'U'

Filter Material

|

Shell

|

Mateial

|

|

Element

|

CS、304、316L、C276、2205、Coating

|

|

Body

|

Meltblown、 glassfibre、PP、 PTFESS;

|

|

gasket

|

Standard NBR, optional Viton

|

|

|

PTFE-coated viton, metal-wound

|

|

|

gaskets

|

Filter Performance Parameters

|

Filtration Accuracy

|

0.003 m~100 m

|

|

Design Temp

|

80C (>80C Requires special design)

|

|

Design Pressure

|

1.0Mpa (>1.0Mpa Requires special design)

|

|

Flow

|

0.1~500m3/h

|

|

Element Q'ty

|

7~300pcs

|

|

Element Lenght

|

250、500、750、1000mm

|

Regardless of the product type or application, our wide range of

high-quality filters and our extensive experience in cartridge

development and production will provide you with unique, practical and efficient solutions.

■ Reduced flushing time

■ Special cartridge can be washed repeatedly

■ Quick change of filter cartridges

■ Longer life

■ Site integrity testing

|

Model

|

Element Size

|

Inlet/Outlet

|

H1

|

H2

|

H3

|

H4

|

L

|

D

|

t1

|

Flow

|

|

MSO-S-7-30

|

7pcs*3"

|

DN50

|

350

|

550

|

1315

|

800

|

473

|

Φ273

|

3

|

7

|

|

MSO-S-10-30

|

10pcs*30"

|

DN65

|

350

|

550

|

1377

|

800

|

525

|

Φ325

|

3

|

10

|

|

MSO-S-13-40

|

13pcs*40"

|

DN80

|

450

|

700

|

1740

|

1000

|

556

|

Φ350

|

3

|

20

|

|

MSO-S-18-40

|

18pcs*40"

|

DN100

|

505

|

800

|

1822

|

1000

|

648

|

Φ400

|

4

|

27

|

|

MSO-S-22-40

|

22pcs*40"

|

DN100

|

505

|

800

|

1859

|

1000

|

698

|

Φ450

|

4

|

33

|

|

MSO-S-29-40

|

29pcs*40"

|

DN125

|

608

|

958

|

1998

|

1000

|

810

|

Φ500

|

5

|

44

|

|

MSO-S-33-40

|

33pcs*40"

|

DN125

|

640

|

1000

|

2044

|

1000

|

860

|

Φ550

|

5

|

50

|

|

MSO-S-40-40

|

40pcs*40"

|

DN150

|

660

|

1025

|

2092

|

1000

|

900

|

0600

|

5

|

60

|

|

MSO-S-52-40

|

52pcs*40"

|

DN150

|

680

|

1100

|

2136

|

1000

|

960

|

Φ650

|

5

|

78

|

|

MSO-S-54-40

|

54pcs*40"

|

DN150

|

720

|

1170

|

2229

|

1000

|

1010

|

Φ700

|

5

|

81

|

|

MSO-S-81-40

|

81ps*40"

|

DN200

|

790

|

1260

|

2339

|

1000

|

1112

|

Φ800

|

6

|

122

|

|

MSO-S-95-40

|

95pcs*40"

|

DN200

|

840

|

1350

|

2458

|

1000

|

1212

|

Φ900

|

6

|

142

|

|

MSO-S-120-40

|

120pcs*40"

|

DN200

|

865

|

1400

|

2534

|

1000

|

1312

|

Φ1000

|

6

|

180

|

Note: 1, t2 ≥ 16; 2, the above flow accuracy in 10 microns, different conditions of different flows, for reference only

Regardless of the product type or application, our wide range of highquality filters and our extensive experience in cartridge development and production will provide you with unique, practical and efficient solutions.

■ Longer life

■ Site integrity testing

■ Reduced flushing time

■ Special cartridge can be washed repeatedly

■ Quick change of filter cartridges

■ Sanitary polished surfaces up to 0.1 µm

■ Electrolyzable

INOCO Green Energy Solutions Co., Ltd. |

Filter Selection Guide

Filter Selection Guide

▍INOCO SCG-W Series Welding - Single Filter Element Filters

▍INOCO SCG-W Series Welding - Single Filter Element Filters