▍INOCO-XF-F SERIES

BACKWASHING FILTER SERIES

Excellent Performance and

Extremely Low Energy Consumption

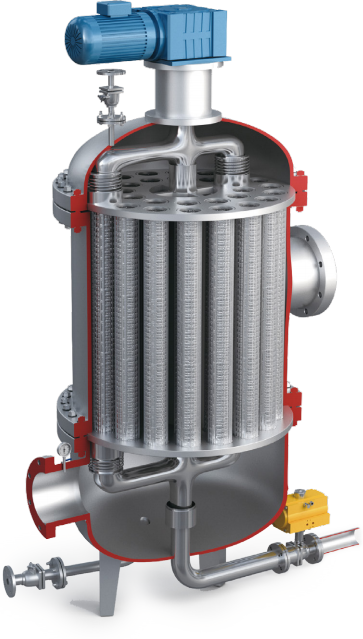

The INOCO-XF-F series full-automatic backwashing filter is a kind of

industrial automatic filters for multiple comprehensive purposes, which can

ensure that the filtered liquid is pure and reliable.

The INOCO-XF-F series are suitable for most of the water filtration standard

applications in terms of handling capacity, precision and reliability, and it

maintains a good operating condition even under harsh operating conditions.

The pressure design of filter body is usually based on the standard design of

ASME U stamped and steel pressure vessels. The filter can also be meet the

specific requirements of other design standards.The main part of the equipment

is made of carbon steel, carbon steel lined with rubber, stainless steel,

dual-phase steel and other materials. At the same time, we can also provide

you with main part made of special materials like titanium and pure nickel.

Core Principle

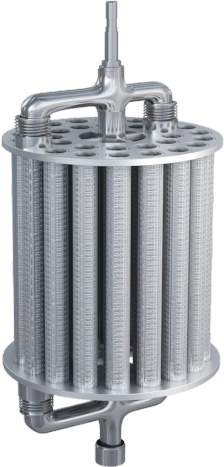

Multiple Filter Elements in A Single Casing

Several separate filter elements are equipped in the filter. Compared with

other single filter-element products of INOCO, with the same chamber diameter,

the filtering area of XF-F series filter increases by multiple times.

Each filter chamber is equipped with an independent filter element assembly

that provides a large filtration surface area and free permeation cross

section and maintains the differential pressure at a very low level.

Since the diameter of filter element is generally no more than 80mm, the

filter element can withstand a high operating differential pressure. When

cleaning, the cleaning components backwashing each group of filter elements

one by one, so that the filtration quality and safety of the filtering process

are fully guaranteed.

Cleaning Principle

Clean Water Backwashing after Filtering

Cleaning process: the single filter unit carries out filtering and

backwashing one by one. Therefore, the filter will not reach a critical level

of contamination. The backwashing operation can be triggered by differential

pressure and/or time. The cleaning (backwashing) process is extremely fast and

thorough; since there is always a set of filter elements in standby mode, the

system pressure remains almost unchanged from beginning to end, and the filter

consumes a very small amount of backwashing detergent.

Product Features

|

Application fields

|

Sea water, river water sewage, grey water, process water, cooling water, circulating water, sealing water, clean water

|

|

Flow rate

|

1-20000m³/H (offshore platform performance exceeding 5000MP)

|

|

Precision

|

5-2000μm

|

|

Design pressure

|

1.0Mpa (up to 10.0Mpa if required)

|

|

Design temperature

|

80℃(Up to-190~380℃ if required)

|

|

Dimension of inlet and outlet

|

DN25-1200

|

|

Valve

|

Standard electric (pneumatic optional)

|

|

Filter standard

|

TSG 21-2016;ASME U;EN

|

|

Casing material

|

Carbon steel, carbon stee lined with rubber(natural rubber, Neoprene), carbon steel lined with PTFE 304,316,S31803,titanium

|

|

Internals material

|

304,316,S31803

|

|

Equipment sealing materal

|

Buna-N (fluororuber, PTFE, metallic gasket optional)

|

|

Materialshaft sealing material

|

Fuororubber(mechanical seal, magnetic seal optional)

|

|

Backwashing control

|

Timer or differential pressure controlled

|

|

Filter element type

|

Cylindrical wedge filter element, tapered weg filter element

|

|

Cleaning method

|

Single suction nozzle, dual suction nozzle, asymmetric

|

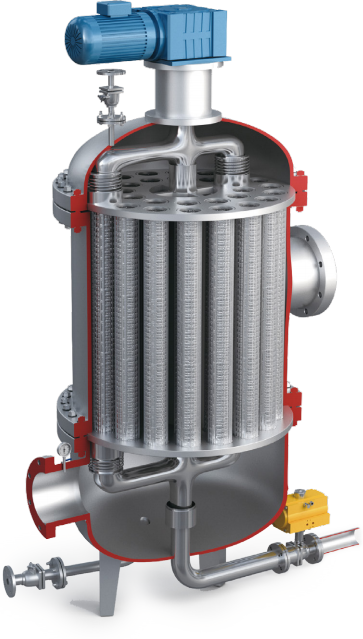

▍INOCO-XF-F FILTER WORKING PRINCIPLE

THE STANDARD VERSION BACKWASHING FILTER

Water Treatment in Most Industrial Working Conditions Suitable for Highly

Polluted Fluids

Unique Advantages

Large filtering area (40㎡)

- Up to 5 micron filtration accuracy

- Very long service life

- Simple and fast cleaning and maintenance

- Backwashing device with precise function

- Non-clogging filter elements

Long-term removal of filtered solid

- Simple operation and compact design

- Low pressure loss

- Low operation cost

- Large filtration flow rate (20000 m³/H)

- Small washing volume

Control System

- Standard 380V, optional 440V, 220V

- Differential pressure, timing, manual cleaning

- Siemens PLC, high stability

- Accept analog signal, and switching signal is optional

- Display the backwashing operation, number of backwashing, and fault

information

- Display screen - optional

- Remote signal, remote control - optional

- Protection level : IP54,optional IP56 and IP 65

- Explosive-proof grade:standard none, Exib II BT4and Exib II CT4 are

optional.

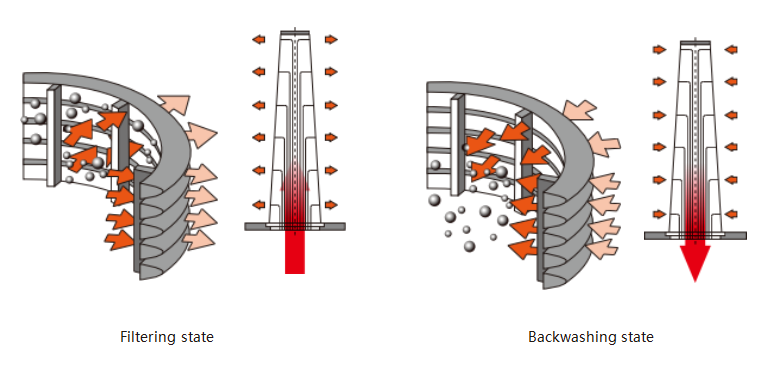

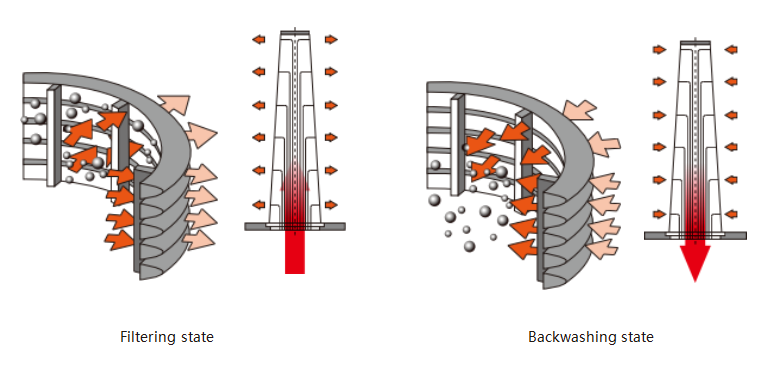

Filtration

In the process of filtering, the water to be filtered passes through the

inlet flange and flows into the filter chamber from below into the filter

elements, which contains organic and inorganic ions will be captured by the

filter elements, and the filtered water will reach the filter outlet through

the filter screen.

Backwashing

The backwashing stage is initiated by differential pressure and/or timer.

During the backwashing process, the filter elements with bottom opening are

alternately flushed in sequence without interrupting the filtering process. To

achieve an alternate flushing, the gear motor drives the flushing arm to

rotate, passing through each of the filter element openings. At the same time,

the flush valve opens. The pressure drop created inside the filter element

(system pressure versus atmospheric pressure) causes the water flowing through

the filter element to flow in the opposite direction, flushing the organic and

inorganic particles trapped in the filter element out of the filter element.

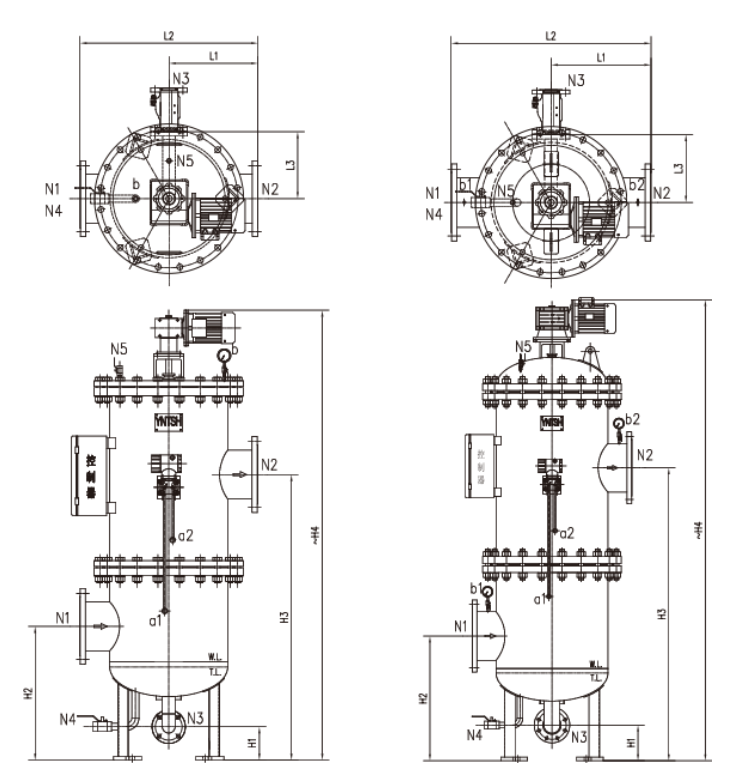

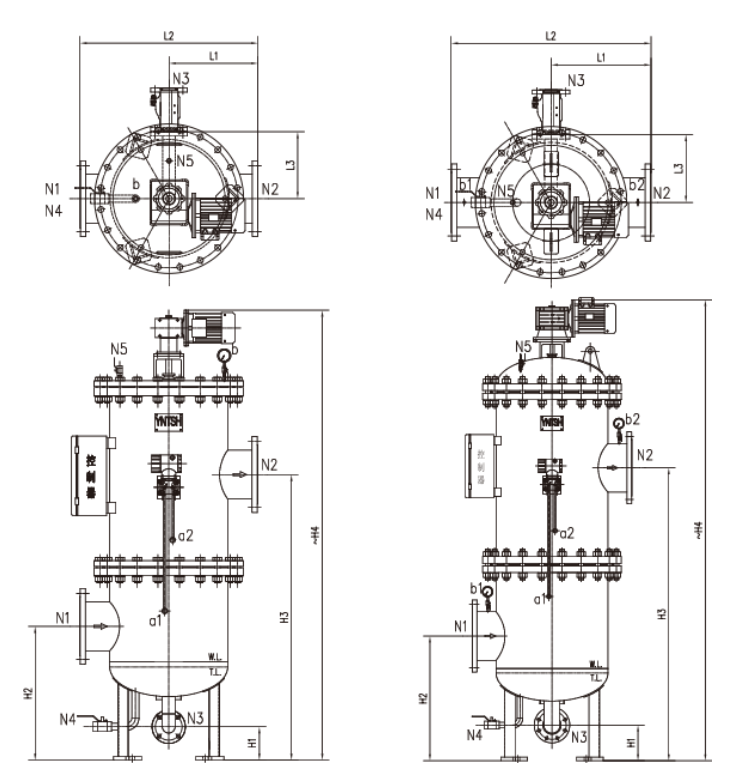

|

Model NO.

|

H1

|

H2

|

H3

|

H4

|

L1

|

L2

|

L3

|

Flow rate m³/h

|

Filtering area ㎡

|

Inlet and outlet diameter DN

|

Drainage diameter DN

|

Amount of blowdown L/time

|

|

XF-F-300

|

150

|

450

|

910

|

1650

|

320

|

640

|

210

|

330

|

0.69

|

150

|

40

|

180

|

|

XF-F-400

|

150

|

560

|

1145

|

1930

|

360

|

720

|

260

|

545

|

1.14

|

200

|

40

|

240

|

|

XF-F-500

|

150

|

650

|

1265

|

2050

|

420

|

840

|

300

|

782

|

1.63

|

250

|

40

|

330

|

|

XF-F-600

|

150

|

680

|

1330

|

2310

|

470

|

940

|

350

|

1255

|

2.61

|

300

|

50

|

500

|

|

XF-F-700

|

150

|

825

|

1660

|

2670

|

560

|

1120

|

400

|

1730

|

3.6

|

350

|

50

|

720

|

|

XF-F-800

|

150

|

900

|

1770

|

2770

|

600

|

1200

|

450

|

2100

|

4.37

|

400

|

50

|

810

|

|

XF-F-900

|

200

|

1025

|

1870

|

3005

|

660

|

1320

|

500

|

2890

|

4.94

|

450

|

80

|

3060

|

|

XF-F-1000

|

200

|

1120

|

2100

|

3310

|

710

|

1420

|

550

|

3430

|

7.14

|

500

|

80

|

3600

|

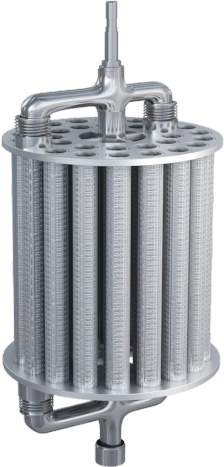

▍INOCO-XF-FV SERIES TAPERED OPTIMIZATION TECHNIQUE

Special solutions required for extremely demanding conditions, Such as

filtering heavily polluted sewage.

INOCO XF-FV series filter elements ingeniously use traditional wedge-shaped

steel wire filter elements to design innovative conical filter elements. The

element material we use stainless steel,dual-phase steel or alloy steel. The

wedge-shaped gap filter element can effectively filter the fluid with less

adhesive and is also suitable for the coarse-filtering field.

The size of wedge-shaped clearance filter element is related to the required

filtration precision, and the V-shape can be designed to be in the direction

of water flow or be opposite to water flow direction. Select different designs

according to different working conditions.

The wedge-shaped steel wire filter element has a bore diameter spanning from

25µm to 1000µm, and has a long service life; some components can be used in

the filter for more than 20 years.

▍INOCO-XF-F SERIES STANDARD FILTER ELEMENT

The INOCO-XF-F series adopts the multi-filter column mode that has a larger

filtering area and is easier to clean compared with other INOCO scraper or

brush structures. The filter element is made of stainless steel, dual-phase

steel or alloy steel. The wedge-shaped gap filter element can effectively

filter the fluid with less adhesive and is also suitable for the

coarse-filtering field.

The advanced mesh shape helps block media that can cause blockage, while the

wedge-shaped filter element is especially suitable for filtration with high

differential pressure.

The size of wedge-shaped clearance filter element is related to the required

filtration precision, and the V-shape can be designed to be in the direction

of water flow or be opposite to water flow direction.

The wedge-shaped steel wire filter element has a bore diameter spanning from

25µm to 1000µm, and has a long service life; some components can be used in

the filter for more than 20 years.

▍INOCO-XF-FS HIGH-PERFORMANCE VERSION

DUAL SUCTION-HIGH-PERFORMANCE VERSION BACKWASHING FILTER

Specially developed for backwashing filters for water treatment under highly

demanding conditions, such as heavily polluted water resources

Typical applied in grey water after flue gas desulfurization, ballast water

Ultra large flow filtration (above 3000M3/h), high precision filtration (5~25

micron)

In order to make the INOCO-XF-FS series backwashing filters achieve optimal

filtration performance under conditions of severe pollution (especially

pollution difficult to eliminate under low working pressure), the dual

backwashing function is adopted by us to enhance the dual filtering principle

(in which, the transverse flow and adverse flow dual-way backwashing is

produced) that is technically mature. The rotating flushing arm is located on

the upper and lower sides of the filter element assembly, and the filter

element is alternately flushed from the upper and lower directions by the

filtering medium (i.e., nonsynchronous flushing), and the process will not be

interrupted at all times. In addition, the newly developed hydrodynamic

components increase the backwashing speed in each filter element column, and

with the dual backwashing system, a thorough flushing of the entire filtration

area is ensured.

The openings at both ends of the filter element allow the water to be

filtered to flow in simultaneously from both ends. Due to its length and the

increased diameter, its filtering area is particularly large. The hydrodynamic

components located in the middle of the filter element also increase the

backwashing speed, thus maximizing the backwashing effect. This maximum

backwashing effect, provided by hydrodynamic components and alternative

flushing function, ensures failure-free operation and greatly reduces the risk

of filter blockage.

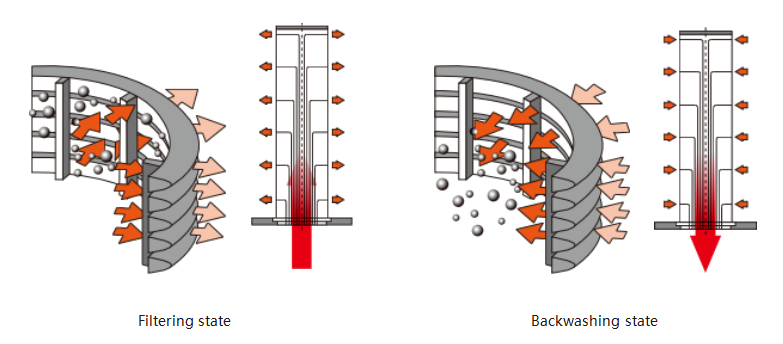

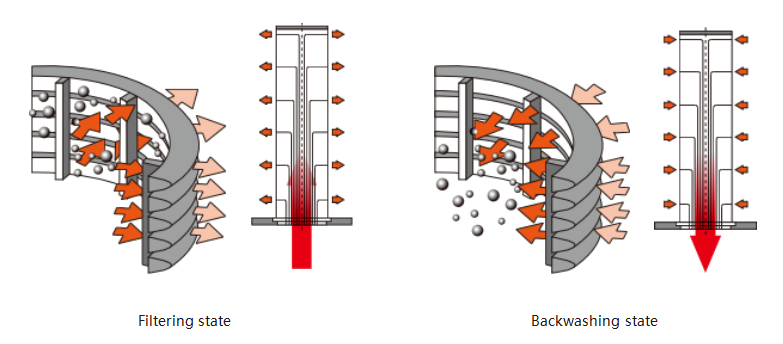

Filtering

During the filtering process, the water to be filtered passes through the

inlet flange and enters the filtration chamber. A portion of unfiltered water

flows through the standpipe in the middle of the filter element into the upper

part of the filter and finally flows into the filter element from above. This

means that the water flows into the filter element from both above and below,

and the organic and inorganic particles contained therein are trapped by the

filter element. The filtered water passes through the filter screen to the

filter outlet.

Backwashing

The backwashing stage is initiated by differential pressure and/or timer.

During the backwashing process, the filter elements with openings at both ends

are alternately flushed up and down in sequence without interrupting the

filtering process. To achieve the alternate flushing, the gear motor drives

the flushing arm to rotate, passing through each of the filter element

openings. At the same time, the flush valve opens. The pressure drop created

inside the filter element (system pressure versus atmospheric pressure) causes

the water flowing through the filter element to flow in the opposite

direction, flushing the organic and inorganic particles trapped in the filter

element out of the filter element.The hydrodynamic element located at the

center of the filter element now increases the backwashing speed and evenly

distributes the backwashing force on the filter element.

Quality management and environmental management

The development, production and sale of all INOCO products are carried out

according to relevant requirements of the ISO 9001 quality management system,

and also meet the specific requirements of the customer. In most cases, INOCO

filters can realize global certification compliance.

After-sales service

The INOCO filter is installed all over the world, so our professional

after-sales service engineers can go to most of the world for debugging, such

as Russia, Dubai, Vietnam, Malaysia, Singapore, etc.

Internet of Things(IoT)

By using the IoT chip, we can provide you with worry-free service by virtue

of the INOCO IoT monitoring platform. The system realizes online services such

as real-time monitoring of equipment working conditions, remote

troubleshooting, and real-time tracking. Engineers, industrial senior service

experts collaborate to provide efficient service model.

Installation

Providing one-stop solution of equipment and installation, from Supplier

Survey→ Design → Equipment Manufacturing → Installation → Debugging → Training

Third party authorized certification

The INOCO filter has obtained accreditation certificates from classification

societies such as China Classification Society (CCS), French Bureau Veritas

(BV) and American Bureau of Shipping (ABS). In addition,it is accepting

certification from more institutions.

▍INOCO-XF-H SERIES

BACKWASHING FILTER SERIES

ULTRA-HIGH PRESSURE SERIES

The INOCO-XF-H series are filters specially developed for ultra-high pressure

working conditions, and its working pressure reaches 100Kg;

Filter is installed at specific locations, such as the offshore oil platform

and the FPSO platform. All INOCO filters can be designed, manufactured,

certified and inspected in accordance with the requirements of GB150-2012,

ASME U standard, and Safety Regulations for Fixed Offshore Platforms. In the

offshore market, the INOCO filters can be fully compliant with all strict

regulations.

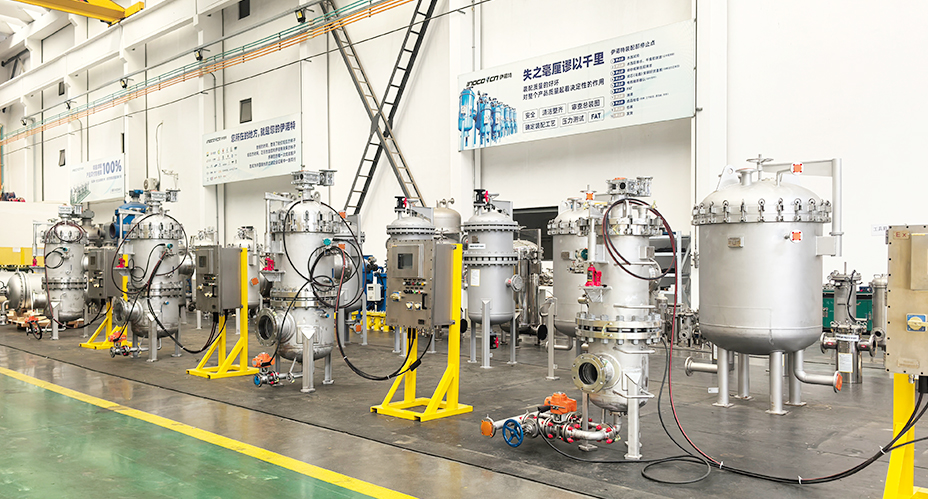

Each of INOCO's modular filters is rigorously tested at the factory to

ensure the overall availability and reliability of the automatic backwashing

filter skid. The automatic backwashing filter skid design guarantees a design

service life of at least 25 years in a marine environment. The INOCO filters

have passed third-party certifications such as TUV, BV and CCS. This is

especially important when the

At the same time, INOCO can accept special materials, such as titanium,

dual-phase steel, Hastelloy materials.

The typical application fields of this filter are mine circulating water,

cooling water, paper plants, etc.

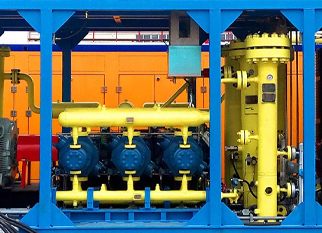

▍INOCO-XF-P SERIES

MODULAR FILTER FOR SPECIAL USE OF OFFSHORE PLATFORMS

Each of INOCO’ s modular filters is rigorously tested at the factory to

ensure the overall availability and reliability of the automatic backwashing

filter skid. The automatic backwashing filter skid design guarantees a design

service life of at least 25 years in a marine environment. The INOCO filters

have passed third-party certifications such as TUV, BV and CCS. This is

especially important when the filter is installed at specific locations, such

as the offshore oil platform and the FPSO platform. All INOCO filters can be

designed, manufactured, certified and inspected in accordance with the

requirements of GB150-2012, ASME U standard, and Safety Regulations for Fixed

Offshore Platforms. In the offshore market, the INOCO filters can be fully

compliant with all strict regulations.

INOCO Green Energy Solutions Co., Ltd. |