▍BAG FILTER

INOCO bag filters are widely used in global industries and have become a standard. Customers can rely on INOCO's standard single-bag or multi-bag filter systems to meet the demanding requirements of various applications. INOCO multi-bag filters offer a selection of 1 to 40 bags. With diverse and advanced filter designs, precision filter bags, and automated configurations, INOCO provides you with optimized solutions.

Filter and Filter Bag Types

|

Bag Filter Types

|

Filter Bag Types

|

|

Quick Opening Bag Filter

|

Standard Type PP, PE Filter Bag

|

|

Multi-Bag Filter

|

Absolute Precision Filter Bag

|

|

Top Entry Bag Filter

|

High Dirt Holding Capacity Pleated Non-woven Filter Bag

|

|

Standard Type Bag Filter

|

Oil Removal Filter Bag

|

|

Sanitary Grade Bag Filter

|

Food Grade Filter Bag

|

|

High Temperature and High Pressure Bag Filter

|

Activated Carbon Filter Bag

|

|

Special Material Bag Filter

|

PTFE, Polyester Filter Bag

|

|

Series Bag Filter

|

Monofilament Nylon Mesh Filter Bag

|

Material

Bag Filter Housing Material Options:

High-Quality Stainless Steel High-

Quality Stainless Steel

Carbon Steel

Hastelloy

Lining

SS304

SS316L, 2205, 2507, 904L 16MnR

C276 (Hastelloy C276), Titanium

PO-lined, PTFE-lined, PTFE-coated,

PFA-coated

Filters can refer to steel pressure vessel GB150, ASME“U”design, manufacturing, and acceptance.

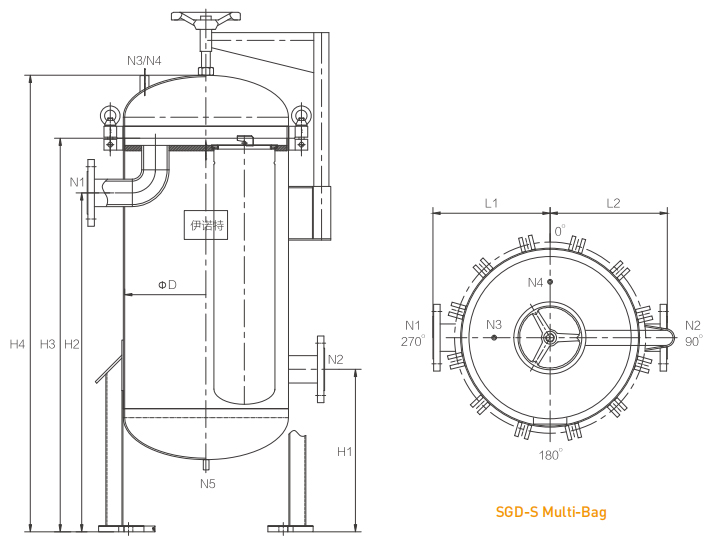

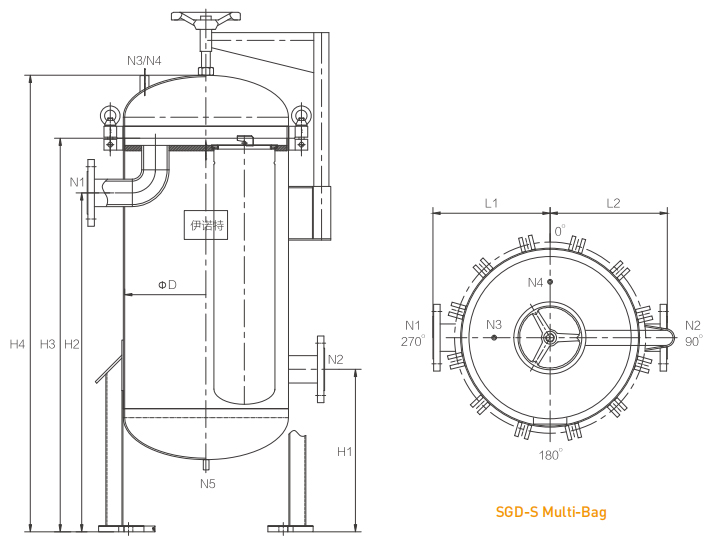

▍INOCO SGD-S Multi-Bag Filter

Easy to operate, with an optimized fluid dynamic design, ideal for high flow and complex, fluctuating processes.

Innotech multi-bag filters are suitable for operating conditions with flow rates ranging from 60 to 5000 M /H. For filters with fewer bags, a handwheel and standard bearing swivel arm are included for easy opening and operation. For filters with 12 or more bags, cylinder or hydraulic assistance is optional, requiring only one person for opening and closing. Auxiliary devices, including pressure relief valves and locating pins, are incorporated to effectively ensure safe equipment operation.

Technical Parameters

Filter Housing Material:

304 (Standard), 2205, 2507, 904L Titanium, Hastelloy PTFE Lining, PTFE Coating

Sealing Ring Material:

Nitrile Rubber (NBR) (Standard),Nitrile Rubber (NBR) (FDA Certified),EPDM (Ethylene Propylene Diene Monomer Rubber),Fluoroelastomer (FKM/Viton),PTFE Encapsulated Fluoroelastomer (FKM)

Filter Bag Material:

PP (Polypropylene) (Standard)

Filter Bag Quantity:

1-24 (Larger sizes require non-standard design)

Filter Bag Type:

Single Bag Filter:1#, 2#, 3#, 4#

Multi-Bag Filter:1#, 2#

Maximum Operating Pressure:

1.0Mpa (150PSI) (10.34bar)

Design Temperature Range:

(Design temperature excludes filter bags)

Carbon Steel:-6 - 250°C

Stainless Steel:-28 - 298°C

Parts in Contact with Filter Media:

Carbon Steel Filter: Carbon Steel

Stainless Steel Filter: Stainless Steel

Inlet/Outlet Connection Surface Treatment:

NPT or Flange

Carbon Steel: Outer surface painted

Stainless Steel: Sandblasted (Standard), Pickled, Polished

Certification:

(For #1, #2 Filter Bag Filters Only)

GB150 “CS” ASME “U” or “UM” Stamp

Filter Bag Seal:

Manual, No Manual Tightening Required (Standard)

Opening Method:

Hinge, Hydraulic or Handwheel Lifting Device

◎ Single, seamless sealing ring minimizes components, simplifying cleaning and enabling rapid filter bag change-outs.

◎ Filter model specifications: accommodates 1 to 40 filter bags.

◎ Elbow upward inlet configuration enhances fluid dynamics.

◎ Select sealing ring material based on chemical compatibility and temperature range.

◎ Manufactured to GB and ASME standards.

◎ Materials of construction include carbon steel, 304 and 316 stainless steel, duplex steel, and Hastelloy.

◎ Manual, pneumatic, spring, and hydraulic cover lifting devices ensure easy operation.

Selection Guide [Filter Sizing]

|

Model /DATA

|

SGD-S2

|

SGD-S2

|

SGD-S3

|

SGD-S3S

|

SGD-S4

|

SGD-S5

|

SGD-S6

|

SGD-S8

|

SGD-S9

|

|

SGD-S10SGD-S12

|

2 SGD-S169

|

SGD-S18

|

3 SGD-S24

|

|

DN

|

65

|

80

|

80

|

100

|

100

|

125

|

150

|

150

|

200

|

200

|

250

|

300

|

300

|

300

|

|

Max Flow Rate

|

50

|

50

|

75

|

75

|

100

|

125

|

150

|

200

|

225

|

250

|

300

|

400

|

450

|

600

|

|

cotnten

|

0.9

|

0.9

|

1.35

|

1.35

|

1.8 3

|

2.25

|

2.7

|

3.6

|

4.05

|

4.5

|

5.4

|

7.2

|

8.1

|

9.0

|

|

母口

|

450

|

450

|

500

|

500

|

550

|

600

|

700

|

750

|

800

|

900

|

1000

|

1100

|

1200

|

1300

|

|

H1

|

250

|

250

|

250

|

250

|

300

|

300

|

350

|

350

|

350

|

350

|

350

|

350

|

350

|

350

|

|

H2

|

916

|

892

|

912

|

874

|

940

|

912

|

954

|

966

|

998

|

897

|

972

|

947

|

947

|

947

|

|

H3

|

1126

|

1119

|

1126

|

1117

|

1182

|

1182

|

1246

|

1261

|

1344

|

1245

|

1376

|

1403

|

1407

|

1407

|

|

H4

|

1289

|

1282

|

1297

|

1288

|

1377

|

1384

|

1486

|

1504

|

1600

|

1626

|

1689

|

1741

|

1776

|

1801

|

|

L1/L2

|

342/348

|

345/348

|

371/373

|

397/373

|

418/398

|

455/423

|

3 487/474

|

512/499

|

578/554

|

646/606

|

666/655

|

705/706

|

755/756

|

805/806

|

|

Vent Port

|

G1/2" Male Thread (with ball valve)

|

Drain

|

G1/2" Male Thread (with ball valve)

|

Pressure Gauge Port

|

1/4" Male Thread(with ballvalve, pressure)

|

Note: The above flow rates are values obtained under the conditions of 0.7MPa working pressure, 5um filtration accuracy, and water as the medium. Flow rates will vary with different pressures, accuracies, and media.

Options and Accessories

◎ Top Cover Opening Method

◎ Hydraulic Lifting Device - Hinged Bolts

◎ Spring Assisted Lifting Device - Hinged Bolts

◎ Quick Opening Top Cover

◎ GB150 TS, ASME U, CE, and CRN Certified Design

◎ Partial Jacket or Full Jacket

◎ Corrosion Allowance

◎ Internal Mesh Screen and Heavy-Duty Basket

◎ Hastelloy C,Alloy 20# Nickel-Chromium-Iron Alloy, 2205 Duplex Stainless Steel (For other materials, please inquire)

◎ Sanitary or Quick Coupling Connection(For other materials, please inquire)

◎ Internal and External Polishing to Sanitary Grade Finish

◎ Sealing Gasket: Silicone, Nitrile Rubber, PTFE Rubber

◎ Filter Bag Material: Polyester, Polypropylene, Nylon, PTFE, Glass Fiber

▍INOCO SGD-S2 Multi-Bag Filter

INOCO multi-bag filters are designed for operating conditions with flow rates ranging from 60 to 5000 M /H. For filters with

a smaller number of bags, a handwheel and a standard bearing swivel arm are included, facilitating easy opening and

operation. For filters with 12 or more bags, pneumatic or hydraulic assistance is available as an option, requiring only a

single operator for opening and closing. Auxiliary devices, such as pressure relief valves and locating pins, are incorporated

to effectively ensure the safe operation of the equipment.

Technical Parameters

Filter Housing Material:

304(Standard), 2205, 2507, 904L, Titanium, Hastelloy, PTFE Lining, PTFE Coating

Sealing Ring Material:

Nitrile Rubber (NBR) (Standard), Nitrile Rubber (NBR) (FDA Certified), EPDM (Ethylene Propylene Diene Monomer Rubber), Fluoroelastomer (FKM/Viton), PTFE Encapsulated Fluoroelastomer (FKM)

Filter Bag Material:

PP(Standard)

Filter Bag Quantity:

1-24(Larger sizes require non-standard design)

Filter Bag Type:

Single Bag Filter:1#, 2#, 3#, 4#

Multi-Bag Filter:1#, 2#

Maximum Operating Pressure:

1.0Mpa (150PSI) (10.34bar)

Design Temperature Range:

(Design temperature excludes filter bags)

Carbon Steel:-6 - 250°C

Stainless Steel: -28 - 298°C

Parts in Contact with Filter Media:

Carbon Steel Filter: Carbon Steel

Stainless Steel Filter: Stainless Steel

Inlet/Outlet Connection: NPT or Flange

Surface Treatment: Carbon Steel: Outer surface painted

Stainless Steel: Sandblasted (Standard), Pickled, Polished

Certification:

(For #1, #2 Filter Bag Filters Only)

GB150 “CS” ASME “U” or “UM” Stamp

Filter Bag Seal:

Manual, No Manual Tightening Required (Standard)

Opening Method:

Hinge, Hydraulic or Handwheel Lifting Device

Selection Reference [Filter Sizing]

|

Model/Specs

|

SGD-F2

|

SGD-F2

|

SGD-F3

|

SGD-F3

|

SGD-F4

|

SGD-F5

|

SGD-F6

|

SGD-F8

|

SGD-F9

|

SGD-F109

|

SGD-F12

|

SGD-F16

|

SGD-F18

|

SGD-F24

|

|

DN

|

65

|

80

|

100

|

125

|

150

|

150

|

200

|

200

|

250

|

300

|

300

|

300

|

300

|

300

|

|

Flow Rate

|

50

|

75

|

100

|

125

|

150

|

200

|

225

|

250

|

300

|

400

|

450

|

600

|

600

|

600

|

|

Filtration Coefficient

|

0.9

|

1.35

|

1.8

|

2.25

|

2.7

|

3.5

|

4.05

|

4.5

|

5.4

|

7.2

|

8.1

|

9.0

|

9.0

|

9.0

|

|

φD

|

450

|

500

|

550

|

600

|

700

|

750

|

800

|

900

|

1000

|

1100

|

1200

|

1300

|

1300

|

1300

|

|

H1

|

250

|

250

|

250

|

250

|

300

|

300

|

360

|

360

|

950

|

980

|

1000

|

1100

|

1100

|

1100

|

|

H2

|

1182

|

930

|

920

|

915

|

910

|

925

|

900

|

970

|

1445

|

1640

|

1500

|

1600

|

1600

|

1600

|

|

H3

|

1362

|

1045

|

1125

|

1140

|

1215

|

1225

|

1240

|

1265

|

1770

|

1910

|

1820

|

1870

|

1870

|

1870

|

|

H4

|

1523

|

1300

|

1325

|

1340

|

1445

|

1470

|

1505

|

1685

|

2100

|

2250

|

2280

|

2290

|

2290

|

2290

|

|

L1/L2

|

348

|

350

|

375

|

415 drain

|

470

|

500

|

550

|

630

|

650

|

750

|

800

|

860

|

860

|

860

|

|

|

G1/2" Male Thread [With ball valve]

|

drain

|

G1/2" Male Thread [with ball valve]

|

Pressure Gauge Port

|

G1/4"Male threaded [with ball valve,pressure gauge port]

|

▍INOCO SGD-H Series of Non-standard Bag Filter

INOCO’s high-pressure filters can operate at 42 MPa and comply with A1/A2 standards as well as the ASME U2

Stamp. For special components, INOCO can perform Finite Element Analysis (FEA) to ensure structural integrity

and performance optimization.

▍INOCO Finite Element Analysis of Filter Element Disc

▍INOCO SGD-S Multi-Bag Filter

The filter bag with the widest range of applications

INOCO SGD-01 filter bags are manufactured from the best available materials, ensuring that all components meet our stringent specifications for filtration performance and purity. Under the guidelines of ISO 902 quality control, we guarantee consistent quality for each filter bag, ensuring no impact on the customer's filtration process. All steel rings and stitching threads are selected according to INOCO's strict standards.

Compatibility with Any Filter

The design and structure of INOCO SGD-01 filter bags are compatible with most existing filters on the market, whether produced by INOCO or other suppliers. We can also produce custom filter bags for non-standard filters.

Materials

The materials used in INOCO SGD-01 filter bags include:

Polypropylene, Nylon, PTFE (Polytetrafluoroethylene),

Polyester, Fiberglass, etc.

INOCO SGD-01 filter bags are capable of handling corrosive chemicals, solvents, and even high-temperature liquids.

|

Specifiation

|

Maximum Flow Rate

|

Filtering Area

|

Diameter

|

Length

|

|

01

|

20.4

|

0.24

|

177.8

|

431.8

|

|

02

|

40.9

|

0.46

|

177.8

|

812.8

|

|

03

|

5.7

|

0.07

|

101.6

|

203.2

|

|

04

|

11.4

|

0.14

|

101.6

|

355.6

|

|

05

|

17.0

|

0.20

|

101.6

|

508

|

|

43

|

5.7

|

0.09

|

88.9

|

304.8

|

|

45

|

11.4

|

0.15

|

88.9

|

508

|

▍INOCO SGD INOCO SGD-01D Large Flow Filter Bag

INOCO 01D series high-flow filter bags are the new generation of liquid bag filters. A single filter bag provides a filtration area of approximately 0.9 square meters, which is 1.8 times that of a traditional standard No. 2 filter bag.

This increases the filtration capacity of a single unit by 1.8 times, marking a significant innovation in the field of liquid bag filtration. The 01D filter bags, when used with dedicated support nets, are compatible with the majority of No. 2 bag filters and multi-bag filter systems available on the market.

▍INOCO SGD-02D High Contaminant Holding Pleated Filter Bag

INOCO pleated filter bags utilize deep three-dimensional

filtration materials, made from 100% pure fibers that are

needle-punched to form a three-dimensional, highly

fluffy, deep-bed structure with a tortuous path for

filtration. The characteristics include a loose fiber

organization, which significantly increases the

contaminant holding capacity and effectively removes

both solid and soft particles. Larger particles are trapped

on the fiber surface, while finer particles are captured

within the deeper layers of the filter media, thereby

achieving high filtration efficiency. The application of

instant sintering technology and calendering treatment

prevents fibers from being lost during filtration when

impacted by high-speed liquids, ensuring no fiber

shedding occurs to contaminate the filtrate.

The filtration accuracy grades:0.5、1、5、10、25、

50、75、100、200……

Filter Bag Materials: Polypropylene, Polyester, Nylon,

PTFE (Polytetrafluoroethylene)

Bag Ring Options: Polypropylene ring, Polyester ring,

Steel ring

▍INOCO SGD-03 Sanitary Filter Bag

• The INOCO SGD-03 sanitary filter bag is designed for the food, beverage, and pharmaceutical industries.

• The INOCO SGD-03 filter bag fully complies with and is recognized for use in the food and beverage industry. It uses materials that strictly meet the requirements of the food industry, ensuring no issues in food applications.

• The filter fibers are not easily shed, reducing the loss of fiber shadows and improving filtration efficiency.

• Independent third-party certification confirms that the filter bag meets GMP and FDA requirements.

• Multi-layer filter bags, fully welded structure eliminates leakage from needle holes.

• Strictly controlled production processes eliminate secondary pollution during storage, handling, and processing.

• Single packaging prevents contamination during transportation, storage, and installation.

• Special handling and storage methods ensure that the package will not be contaminated after packaging.

▍INOCO SGD-04 The Absolute Precision Filter Bag

High-efficiency performance

SGD-04 filter bags are particularly suitable for applications with strict requirements on filtration efficiency, ensuring over 99% efficiency and providing precise filtration from 1 to 25 microns.

Main features of the filter bags

◎ 100% Full Welded Joint Technology: Ensures structural stability and durability.

◎ Safe and Stable Sealing Ring: Provides reliable sealing to prevent unfiltered fluid bypass.

◎ 100% Pure Melt-blown Polypropylene or Polyester Construction: Guarantees material consistency and high-efficiency filtration performance.

◎ No Addition of Any Resin, Adhesive, or Surface Treatment: Avoids the risk of secondary pollution and enhances safety in use.

◎ Made from FDA-approved Materials: Manufactured using materials approved by the US Food and Drug Administration

(FDA) for food contact.

◎ All Filter Bags Composed of Materials Listed by the FDA as Safe for Food Contact: Further emphasizes its suitability for the food and beverage industry.

Application

• Filtration of beer, wine, whiskey, and other beverages

• Removal of fine particles during parts cleaning

• Final filtration of porcelain paints

• Final filtration of vinegar

• Removal of activated carbon

• Final filtration of hydraulic oils and lubricants

Filter Bag Performance Specifications

|

Series

|

Material

|

Fitrtion Type

|

Application Code

|

Fitration curacy

|

|

Standard Filter Bag

|

PO/PE/NMO

|

Relative & Absolute Fitraion

|

1#/2#/3#/4#/5#

|

0.5-1000

|

|

Wear-resistant Needle Felt Bag

|

PP/PE/PTFE

|

Deep Relative Filtration

|

1#/2#/3#/4#/5#

|

0.5-2000

|

|

Wear-resistant Mesh Filter Bag

|

NMO/PP/PE

|

Surface Relative Filtration

|

1#/2#/3#/4#/5#

|

25-2000

|

|

Multi-layer Fiter Bag

|

PP/PE

|

Deep Relative Fittration

|

1#/2#

|

|

|

Absolute Precision FitterBag

|

PP/PE

|

Deep Absolute Filtration

|

1#/2#

|

0.2-50

|

|

Utra-long Life Fiter Bag

|

PP/PE

|

Surface Relative Filtrtion

|

1#/2#/

|

|

|

Activated Carbon Filter Bag

|

PP/PE

|

Deep Adsorptio Filtration

|

1#/2#/5#

|

1-100

|

|

Oil-Absorbent Filter Bag

|

PP

|

Deep Relative Filtration

|

1#/2#/5#

|

1-50

|

|

Pleated Filter Bag

|

PP

|

Deep Absolute Filtration

|

1#/2#

|

1-50

|

|

Anode Filter Bag

|

PE/PP

|

Surface Relativ Fittration

|

Customized

|

50-200

|

Filter Flow Direction Configuration Guide

▍INOCO Bag Filter Model Specifications

① Manufacturer abbreviation ② Filter model abbreviation

③ Device housing material Number of filter bags in the housing

S-Stainless Steel C-carbon steel P-Duplex Steel C0-Carbon

Steel with PO lining CP-Carbon Steel with PP lining

Numbers indicate the quantity of filter bags.

For example: 3 = 3-bag filter

N-Nickel Alloy

CE-Carbon Steel with

PTEE lining

H-Hastelloy

④ Flange specification

PL-Plate Flange SO-Slip-On Flange WN-Weld Neck Flange

Numbers indicate nominal flange diameter。For example:100=DN100

⑤ Flange sealing face type

RF-Raised Face F F - F l a t Face R J - Ring Joint M F M-Male-Female Face T G - Tongue and Groove

⑥ Flange standard

HG-Chinese Ministry of Chemical Industry

DIN-German Standard

JIS-Japanese Standard

GB-Chinese National Standard

ANSI-American Standard

⑦ Pressure rating

For example:P06=PN6

⑧ Filtration accuracy

For example:5=5µm

⑨ Surface treatment

A-Sandblasted B-Polished C-Electro- E-Epoxy Coated F-Phosphated J-Degreased

polished a/b = External Sandblasted / D-Painted

⑩ Flow direction configuration

Internal Polished

For example:T8=TYPE8

INOCO Green Energy Solutions Co., Ltd. |