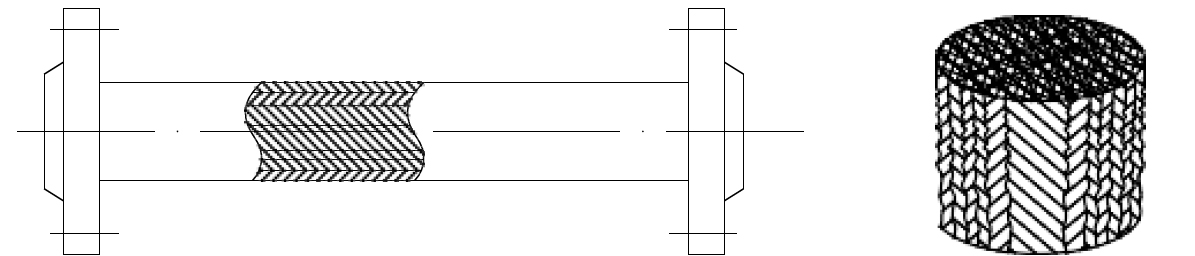

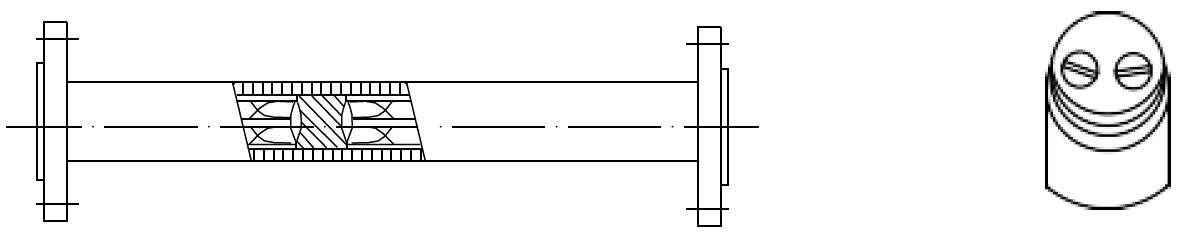

SV Type Static Mixer

The SV unit is a cylindrical structure assembled from corrugated plates of a specified specification.

Liquid-liquid and gas-gas phase heterogeneity are coefficients σX ≤ 1-5%.

Suitable for liquid-liquid, liquid gas, and gas gas mixing, emulsification, reaction, absorption, extraction, and enhanced heat transfer processes with viscosity ≤ 10² centipoise. dh≤3.5, Suitable for cleaning media with a concentration of ≤ 10² centipoise: dh≥5, The application medium may be accompanied by a small amount of non adhesive impurities.

Model Specifications

|

DN

|

dh

|

Q

|

Model Specifications

|

DN

|

dh

|

Q

|

|

SV-2.3/20

|

DN20

|

2.3

|

0.5-1.2

|

SV-5~20/200

|

200

|

5-20

|

56-110

|

|

SV-2.3/25

|

DN25

|

2.3

|

0.9-1.8

|

SV-5~20/250

|

250

|

5-20

|

88-176

|

|

SV-3.5/32

|

DN32

|

3.5

|

1. 4-2.9

|

SV-5~30/300

|

300

|

5-30

|

125-250

|

|

SV-3.5/40

|

DN40

|

3.5

|

2.2-4.5

|

SV-7~30/350

|

350

|

7-30

|

173-346

|

|

SV-3. 5/50

|

DN50

|

3.5

|

3.5-7

|

SV-7~30/400

|

400

|

7-30

|

226-452

|

|

SV-5/80

|

DN80

|

5

|

9-18

|

SV-7~30/500

|

500

|

7-30

|

353-706

|

|

SV-5/100

|

DN100

|

5

|

14-28

|

SV-7~30/600

|

600

|

7-30

|

505-1010

|

|

SV-5~7/150

|

DN150

|

5-7

|

30-60

|

SV-15~30/1200

|

1200

|

15-30

|

1630-3260

|

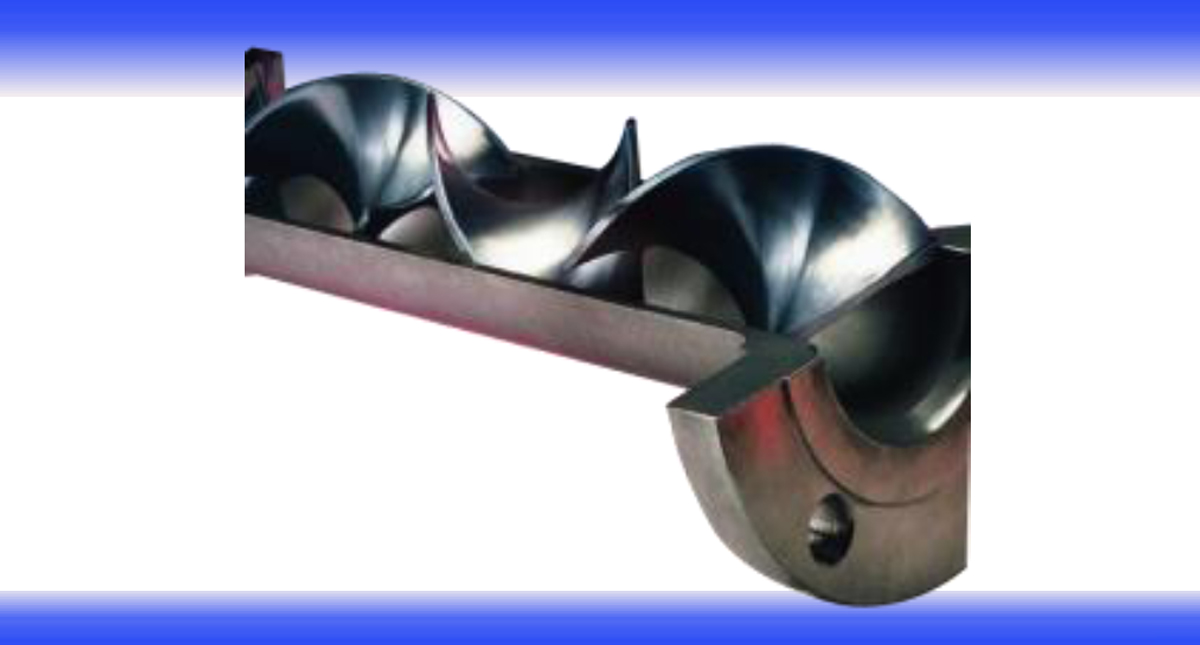

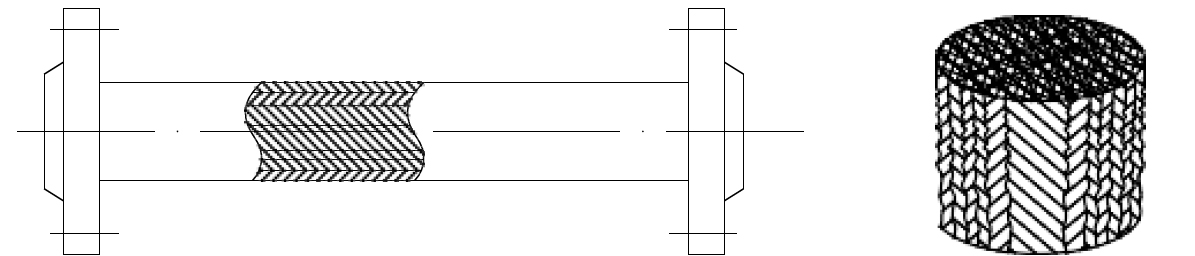

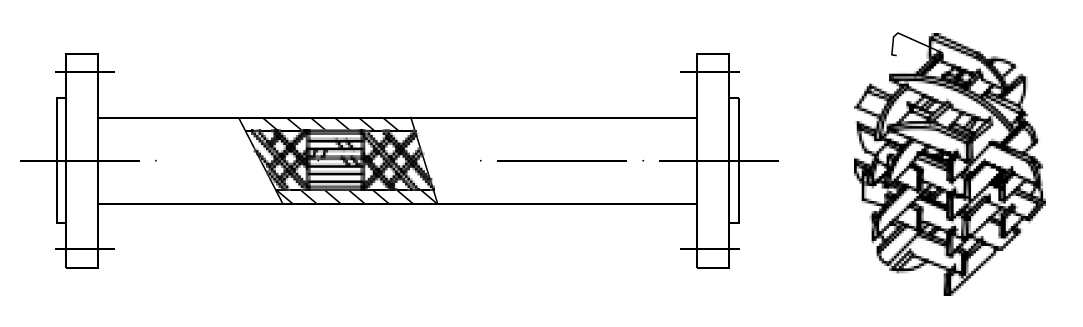

SK Type Static Mixer

The SK type unit is composed of spiral plates welded together by twisting the left and right sides of a single channel.

The coefficient of non-uniformity for liquid-liquid and liquid-solid phases is: σ X ≤ √1-5%.

Suitable for mixing, reaction, extraction, absorption, injection molding, color matching, heat transfer and other processes in the fields of chemical, petroleum, pharmaceutical, food, fine chemical, plastic processing, environmental protection, synthetic fiber, mining and metallurgy. Especially suitable for high viscosity media with high flow rate and mixed impurities and viscosity ≤ 104 centipoise.

|

Model Specifications

|

DN

|

dh

|

Q

|

Model Specifications

|

DN

|

dh

|

Q

|

|

SK-5/10

|

20

|

5

|

0.15-0.3

|

SK-50/100

|

100

|

50

|

14-28

|

|

SK-7.5/15

|

25

|

7.5

|

0.3-0.6

|

SK-62/125

|

125

|

62

|

22-44

|

|

SK-10/20

|

32

|

10

|

0.6-1.2

|

SK-75/150

|

150

|

75

|

31-64

|

|

SK-12.5/25

|

40

|

12.5

|

0.9-1.8

|

SK-100/200

|

200

|

100

|

56-110

|

|

SK-16/32

|

50

|

16

|

1.4-3.2

|

SK-125/250

|

250

|

125

|

88-177

|

|

SK-20/40

|

80

|

20

|

2.2-4.5

|

SK-150/300

|

300

|

150

|

127-255

|

|

SK-25/50

|

100

|

25

|

3.5-7.0

|

SK-200/400

|

400

|

200

|

226-452

|

|

SK-40/80

|

150

|

40

|

9-18

|

SK-250/500

|

500

|

250

|

353-706

|

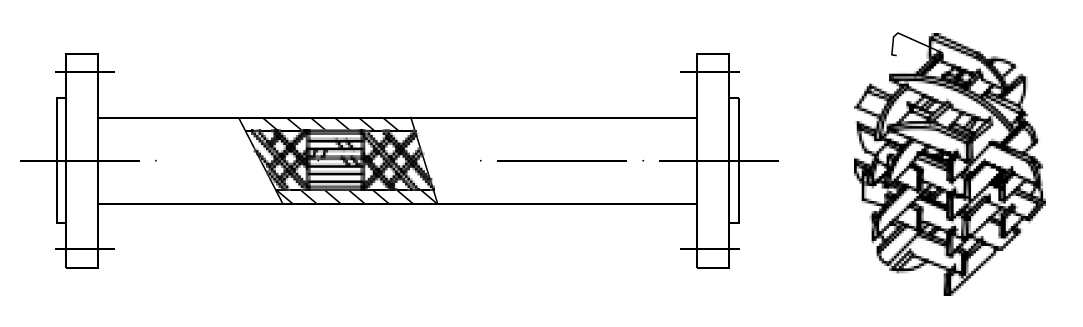

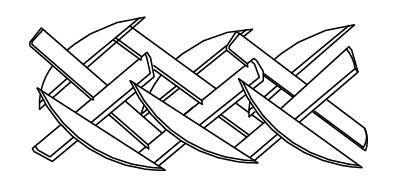

SX Type Static Mixer

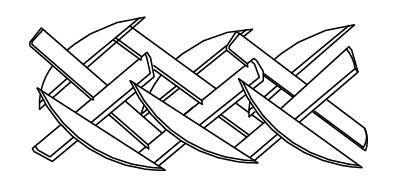

SX type units are composed of intersecting horizontal bars that form many X-type units according to a certain pattern.

Technical feature: The mixing non-uniformity coefficient is σ X ≤ √1-5%.

Suitable for medium-to-high viscosity liquid-liquid mixing with viscosities ≤104 centipoise, reaction and absorption processes, or the mixing and reaction of polymer streams. It performs best when handling large volumes.

The effect is better when used in large quantities.

|

Model Specifications

|

DN

|

dh

|

Q

|

|

SX-12/50

|

50

|

12

|

3.5-7.0

|

|

SX-16/65

|

65

|

16

|

6-12

|

|

SX-20/80

|

80

|

20

|

9-18

|

|

SX-25/100

|

100

|

25

|

14-28

|

|

SX-31/150

|

125

|

31

|

22-44

|

|

SX-50/200

|

150

|

50

|

56-110

|

|

SX-62/250

|

200

|

62

|

88-176

|

|

SX-75/300

|

250

|

75

|

125-250

|

|

SX-87/350

|

350

|

87

|

173-346

|

SL Type Static Mixer

The SL type unit is composed of crossed horizontal bars according to a certain pattern to form a single X-type unit.

Technical Features: Liquid-liquid and liquid-solid phase mixing, with heterogeneity coefficients of σ X ≤ √1-5%.

Suitable for the operation of heat exchangers, heating or cooling units for viscous products in industries such as chemical, petroleum, and oil, with viscosity ≤ 106 centipoise or mixed with high polymer fluids, while conducting heat transfer, mixing, and heat transfer reactions.

|

Model Specifications

|

DIN

|

dh

|

Q

|

|

SL-12/25

|

25

|

12

|

0.7-1.4

|

|

SL-16/32

|

32

|

16

|

1. 4-2 9

|

|

SL-20/40

|

40

|

20

|

2. 3-4 6

|

|

SL-25/50

|

50

|

25

|

3.5-7

|

|

SL-40/80

|

80

|

40

|

9-18

|

|

SL-50/100

|

100

|

50

|

14-28

|

|

SL-75/150

|

150

|

75

|

32-64

|

|

Model Specifications

|

DIN

|

dh

|

Q

|

|

SL-100/200

|

200

|

100

|

56-110

|

|

SL-125/250

|

250

|

125

|

88-176

|

|

SL-150/300

|

300

|

150

|

127-255

|

|

SL-175/350

|

350

|

175

|

173-346

|

|

SL-200/400

|

400

|

200

|

226-452

|

|

SL-250/500

|

500

|

250

|

353-706

|

|

SL-300/600

|

600

|

300

|

410-814

|

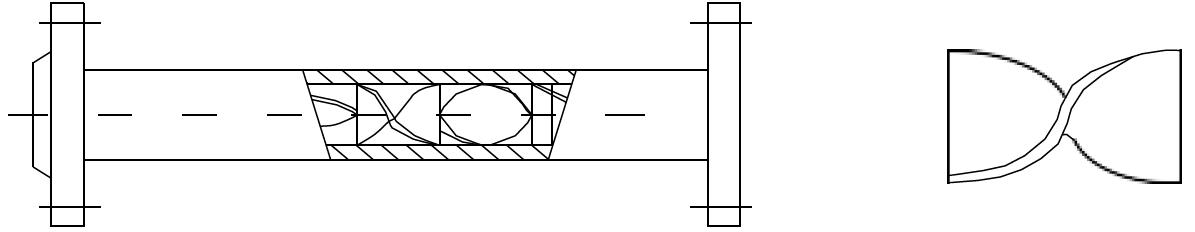

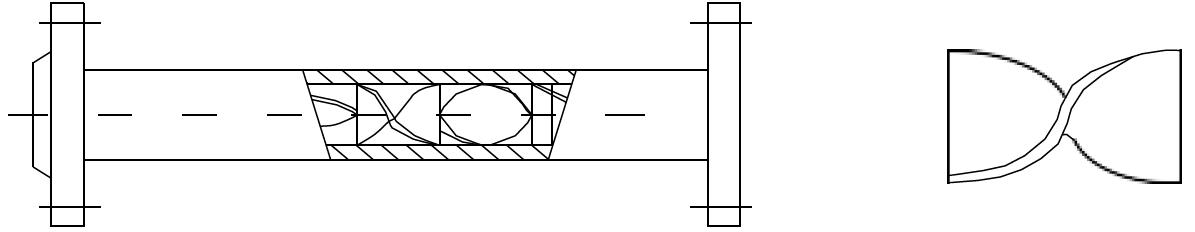

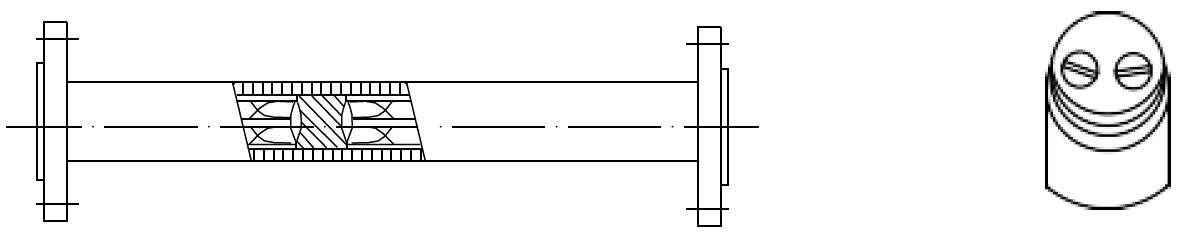

SH Type Static Mixer

The SH unit consists of a double channel with spiral vanes placed inside. The channels of adjacent units are offset by 90°, and a fluid redistribution chamber is located between the units.

Technical features: The highest dispersion degree is 1-2μm, and the unevenness of liquid-liquid phase is σ X ≤ √1-5%.

Suitable for mixing, emulsification, color matching, injection molding, spinning, and heat transfer processes in the fine chemical, plastics, synthetic fiber, and mining sectors. It is particularly suitable for clean media with low flow rates and high mixing requirements (≤106 centipoise).

|

Model Specifications

|

DN

|

dh

|

Q

|

|

SH-12/25

|

25

|

12

|

0. 7-1. 4

|

|

SH-16/32

|

32

|

16

|

1. 4-2 9

|

|

SH-20/40

|

40

|

20

|

2.3-4.6

|

|

SH-25/50

|

50

|

25

|

3.5-7

|

|

SH-40/80

|

80

|

40

|

9-18

|

|

SH-50/100

|

100

|

50

|

14-28

|

|

SH-75/150

|

150

|

75

|

32-64

|

|

Model Specifications

|

DN

|

dh

|

Q

|

|

SH-100/200

|

200

|

100

|

56-110

|

|

SH-125/250

|

250

|

125

|

88-176

|

|

SH-150/300

|

300

|

150

|

127-255

|

|

SH-175/350

|

350

|

175

|

173-346

|

|

SH-200/400

|

400

|

200

|

226-452

|

|

SH-250/500

|

500

|

250

|

353-706

|

|

SH-300/600

|

600

|

300

|

410-814

|

[Precautions]

Engineering designs generally use a single or series static mixer to achieve mixing. If two static mixers are operated in parallel, the piping design should ensure uniform fluid distribution.

When using small-sized SV type, if the medium contains impurities, two parallel switching filters (such as SBL-S type filters) should be installed before the mixer. The filter size is generally selected as a stainless steel filter with a mesh of 40-20 mesh.

Flow, temperature, pressure, and other indicator instruments and test points should not be installed on the static mixer as much as possible. Special requirements should be stated when ordering. If a heat exchange jacket is required on the mixer housing, this should be stated when ordering.

INOCO Green Energy Solutions Co., Ltd. |