Specification

1. The core internal element is micron porous tubes which is under hung in the filter body, and the bottom is equipped with an auxiliary filter zone for making sure the filtration effect.

2. The filter internal structure is not only having less spacerequirement, but also have more filtration area, main solution is to solve the medium quick filtration on the top, and the middle or the bottom have auxiliary filtration, then the trapped filter cake could be washed and dry pressed.

3. INOCO-DS-A6 could finish the processing of filtering, static washing, dry pressing in one machine, it shortens the process, avoids the outside pollution to the cake, closed filtering, clean production; and the pneumatic quick open cover has simple operation.

4. Discharging the dry cake and reducing the follow-up process energy consumption.

Application Cases

Water treatment:

1. Industry water, waste water, river water, groundwater, microfiltration

2. Oilfield reinjection water filtration;

3. Fly ash filtration in the wastewater of coal gasification units;

4. Electroplating wastewater, PCB wastewater, battery waste water, mine waste water, Magnetic material wastewater and containing sulfur wastewater, fluorine containing wastewater, containing dust wastewater.

Product Performance

1. High filtration efficiency, with the highest filtration accuracy of 0.3um;

2. Life is long, the longest continuous service life up to 10 years, at least two to three years;

3. Chemical corrosion resistance is superior, all kinds of acid, alkali, salt resistance of 90 DEG, non-toxic, tasteless, no agent dissolution, mechanical performance is good, not easy to damage;

4. PE microporous material temperature resistance≤80°C, PA≤100°C.

5. High mechanical strength, especially impact strength is good, not easy to damage;

6. Easy to reverse blow high regeneration efficiency.

INOCO-DS-A7 Series tube type automatic filter / thickener

Equipment description

INOCO-DS-A7 series tube type automatic filtration system can automatically regenerate filter elements without stopping the system. It is a fully automatic self-cleaning filter that effectively reduces the need for manual cleaning and does not require replacement of filter elements. It is widely used in continuous production, high-risk operating environments, and situations where metal filter elements are not suitable.

Working principle

The feed liquid with the catalyst enters from the outside of the filter and passes through the filter material from the outside to the inside.

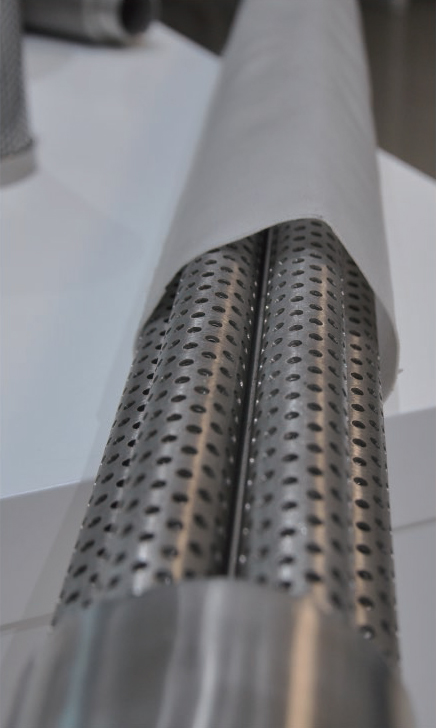

Solids collect on its surface and form a uniform cake. The cake remains on the �lter elements due to their concave-convex pro�le and a continually maintained pressure di�erential across them.

When the pressure drop to the set value, inlet and outlet valve turn o�ff, compressed air flow into the filter and dry the filter cake, in the backwashing processing, the particles will be removed, and the filter element could be regenerate.

After the pre-filtration step comes a filtration step of varying length, which terminates as the feed stops. Unloading is achieved through reverse blowing, but there is no need to empty the liquid inside the machine. This step causes the filter cake to fall off and sink to the cone of the filter within seconds after backblowing, and then the filtration cycle returns to normal.

The thickened thick slurry is discharged from the machine by opening the discharge valve in the next filtration cycle, which has no impact on the filtration steps.

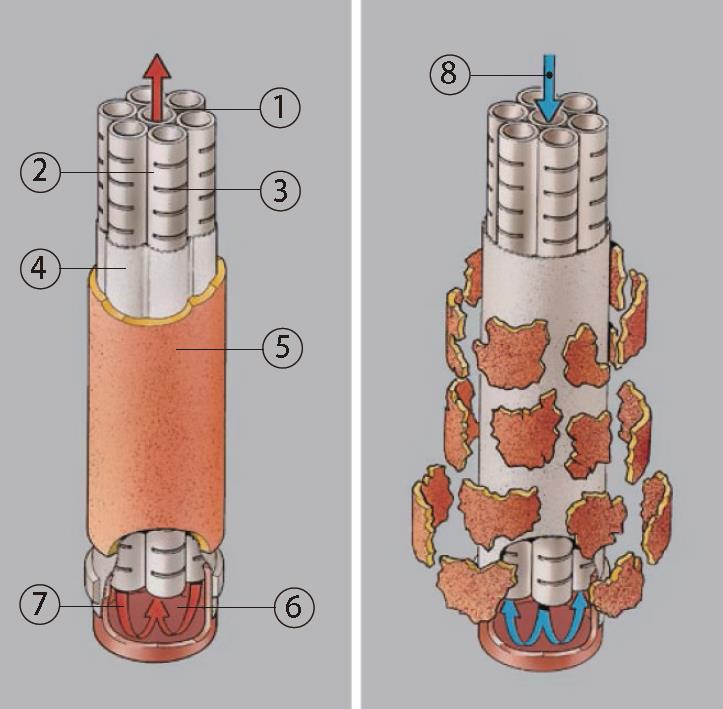

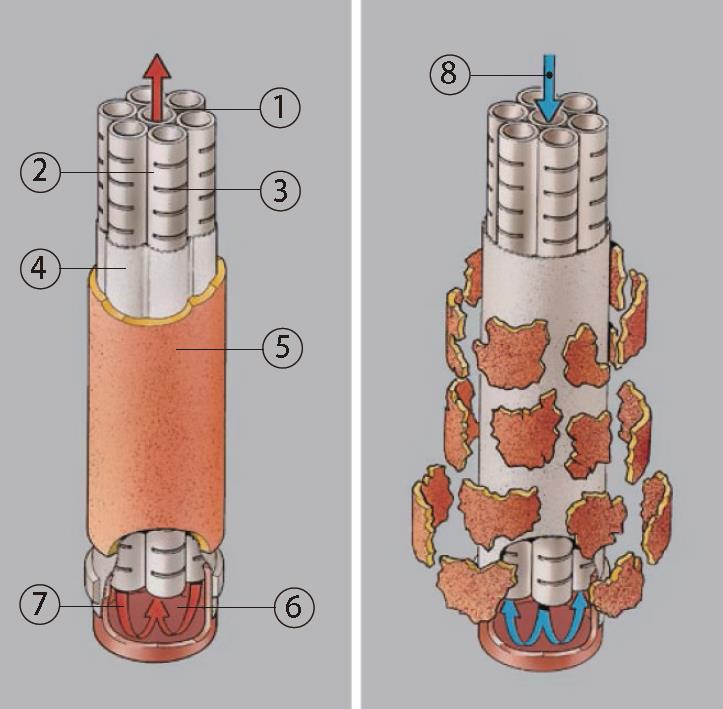

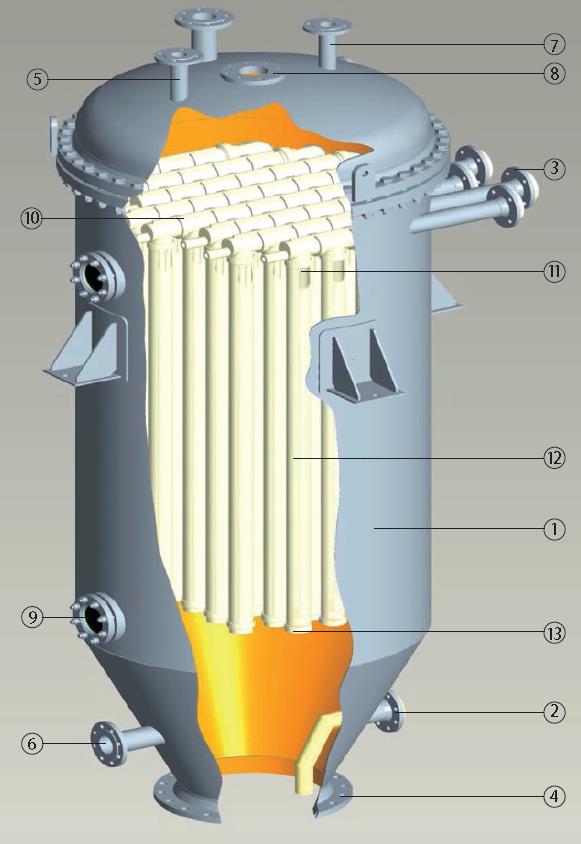

1. central tube

filtrate collector with solid wall total displacement of filtrate from the fi�lter element.

2. filter tube

support for filter medium

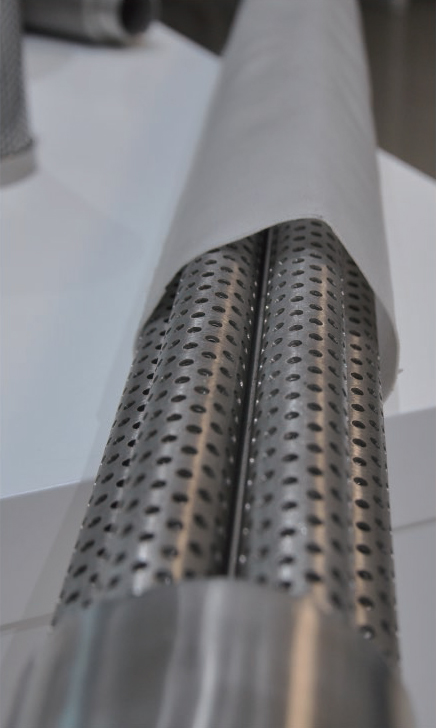

3. typical apertures on filter tubes

4. filter medium

pressed against the bundled filter tubes during filtration

5. filter cake

6. collection chamber

connecting central tube(1) with filter tubes(2)

7. filtrate

exits filter element through central tube

8. blow-back gas

initiates the discharge of the filter cake

Character

Dry and wet material discharge;

Filtered solids are dehydrated and discharged via gas backflushing;

Can also be used for filter cake re-reaction;

Continuous thickening;

Permits uninterrupted filtration, with solids flushed back into the liquid for slurry discharge;

Suitable for processes requiring continuous filtration;

Sanitary filters;

Designed to meet the high production standards of pharmaceuticals and fine chemicals. All product contact surfaces and components can be effectively cleaned.

Back-blown

Whether using dry or wet discharge, discharge is achieved by applying reverse pressure to the filter rod.

The unique structure facilitates backflushing:

During backflushing, the filter cloth rapidly expands outward, particularly in the area where the filter cake adheres, causing vertical cracks in the filter cloth. The instantaneous backflushing of gas (such as air or nitrogen) within the filter cloth rapidly ejects the cracked filter cake from the cloth.

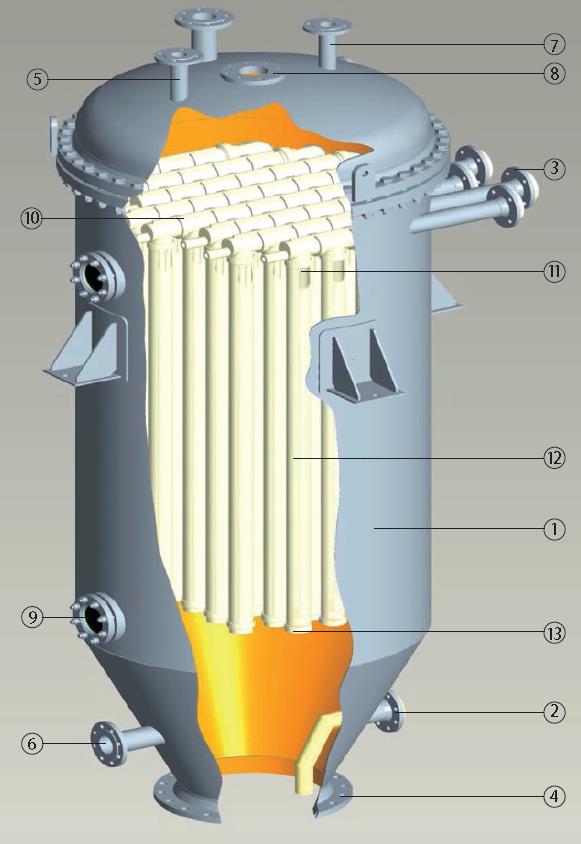

1. Filter housing - pressure vessel

2. Flow port

3. Reverse blowing port

4. Solid-residue discharge outlet

5. Overflow and exhaust port

6. Product feed port

7. Instrumentation port

8. Saddle flange for heel filtration spray jet nozzle

9. Inspection port

10. Branch pipe

11. Filter element

12. Filter medium(frame membrane etc.)

13. Cloth clamp ring

This filter system has been successfully applied in many fields.

Classic application:

★ Titanium dioxide

★ The current board

★ Viscose �ber

★ Nickel production

★ Flue gas desulfurization

★ Wastewater treatment

★ Resin

★ The production of PVC

★ Removal of the catalyst

★ Phosphating

★ Activated carbon

★ Zeolite production

★ The production of edible oil

★ Chlor alkali production

★ Polyol

★ Gas desulfurization

INOCO Green Energy Solutions Co., Ltd. |