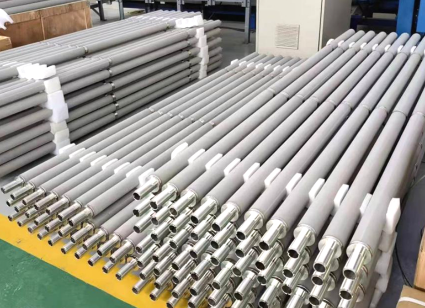

The mixing process in a static mixer is performed by a series of mixing units of varying sizes installed in a hollow pipe. The mixing units cause the fluid to rotate alternately, sometimes counterclockwise and sometimes counterclockwise, constantly changing flow direction. This not only pushes the central fluid toward the periphery but also pushes the peripheral fluid toward the center, resulting in excellent radial mixing. Simultaneously, the fluid's own rotation also occurs at the interfaces between adjacent components. This perfect radial circulation mixing action ensures uniform mixing of materials.

This static mixer is designed, manufactured and accepted in full compliance with the industry standard JB T7660-95 "Static Mixer".

[Application Scope]

Static mixers can be used in processes such as liquid-liquid, liquid-gas, liquid-solid, and gas-gas mixing, emulsification, neutralization, absorption, extraction, reaction, and heat transfer enhancement. They can be used in a wide range of viscosities and under various flow patterns (laminar, transitional, and turbulent) for both intermittent and continuous operation. The following briefly describes the scope of different applications.

(1) Liquid-Liquid Mixing

Good mixing can be achieved for fluids with viscosity in the range of 10 6 Mpa · s, from laminar to turbulent flow. Theminimum diameter of dispersed droplets can reach 1-2 μ m, and the size distribution is uniform.

(2) Liquid-Gas Mixing

Static mixers enable continuous renewal and full contact between the liquid-gas phase interface, and under certain conditions can replace bubble and sieve-plate columns.

(3) Liquid-Solid Mixing

When a small amount of solid particles or powder (solids occupying approximately 5% of the liquid surface area) is mixed with a liquid under turbulent flow, using a static mixer can force the solid particles or powder to be fully dispersed, achieving the desired extraction or decolorization of the liquid.

(4) Gas-Gas Mixing

Can be used to mix cold and hot gases, or different gas components.

(5) Enhanced Heat Transfer

The static mixer increases the contact area of the fluid, which increases the heat transfer coefficient. Generally speaking, for cooling or heating a gas, the heat transfer coefficient can be increased by 8 times if a static mixer is used; for heating a viscous liquid, the heat transfer coefficient can be increased by 5 times; for condensing a gas with a large amount of non-condensable gas, the heat transfer coefficient can be increased by 8.5 times; for heat transfer of polymer melts, the temperature and viscosity gradients on the pipe cross section can be reduced.

INOCO Green Energy Solutions Co., Ltd. |

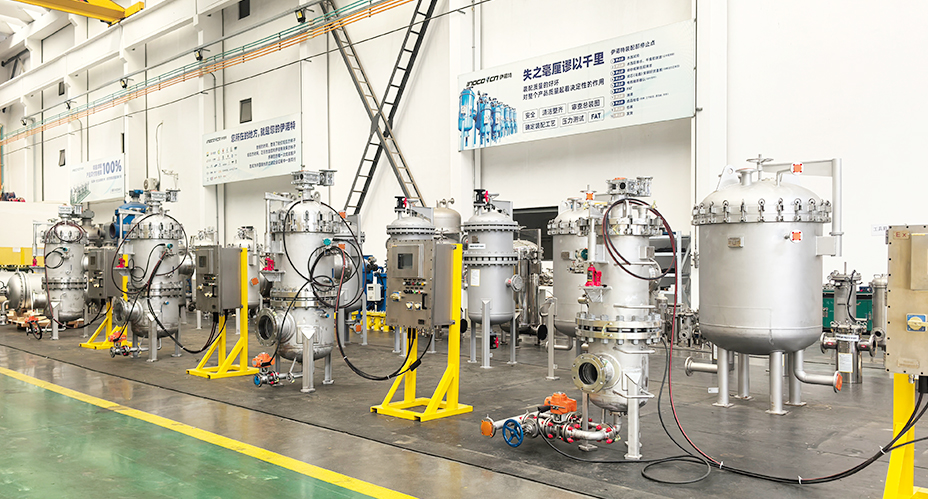

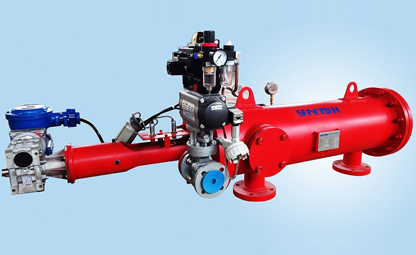

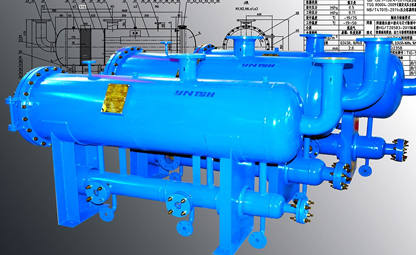

Backwashing Filter Series

Backwashing Filter Series

Self-cleaning Filter Series

Self-cleaning Filter Series

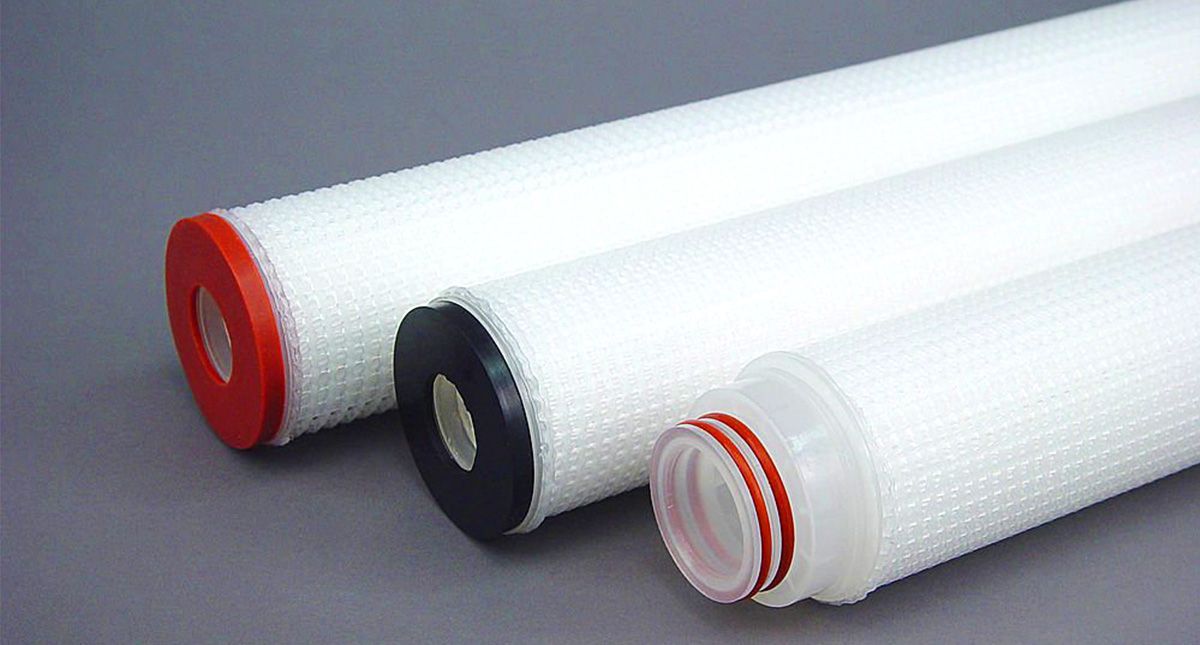

Cartridge Filter

Cartridge Filter

High-flow Filters

High-flow Filters

Scanning Automatic Self-cleaning Filter

Scanning Automatic Self-cleaning Filter

Internal Scraper Automatic Self-cleaning Filter Series

Internal Scraper Automatic Self-cleaning Filter Series

Side-entry Single Bag Filter

Side-entry Single Bag Filter

Bag Filter

Bag Filter

Liquid - Liquid Separation Filter

Liquid - Liquid Separation Filter

Carbon Steel and Anticorrosive Basket Filter

Carbon Steel and Anticorrosive Basket Filter

Media Filter

Media Filter

Activated Carbon Filter

Activated Carbon Filter

Microporous Filter

Microporous Filter

Static Mixer Series

Static Mixer Series