▍Media Filter

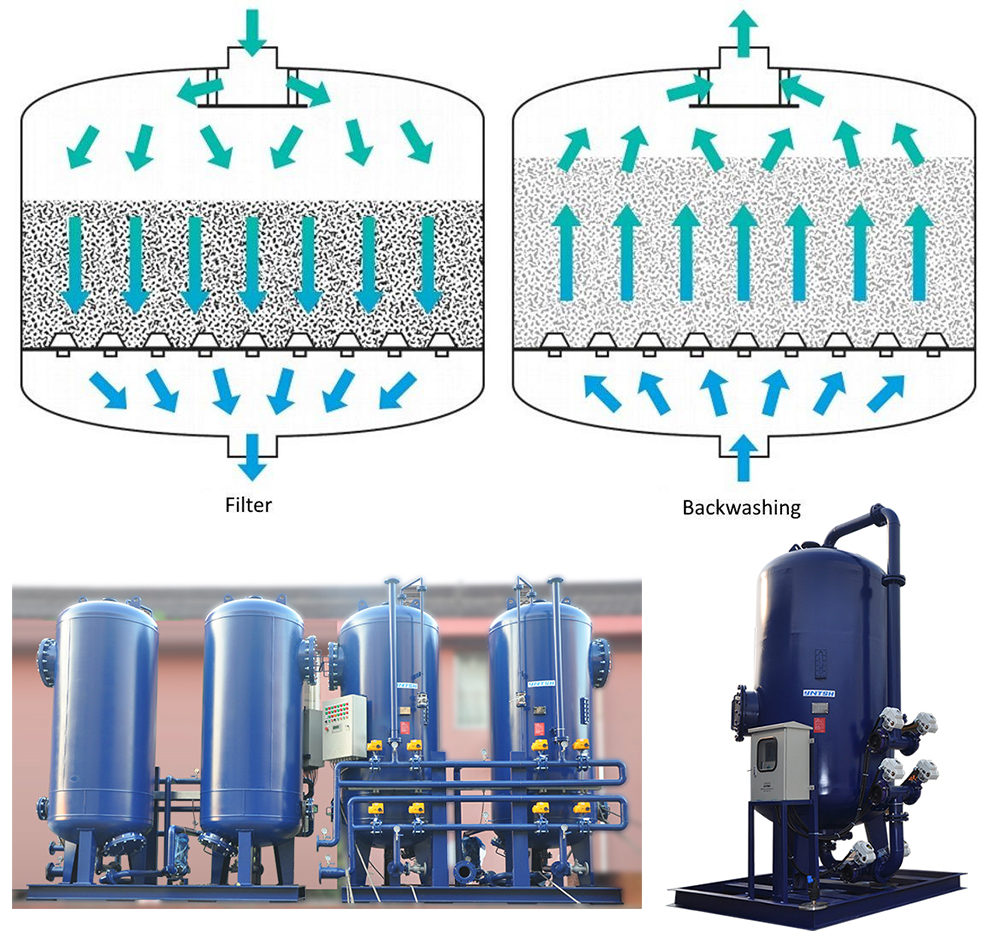

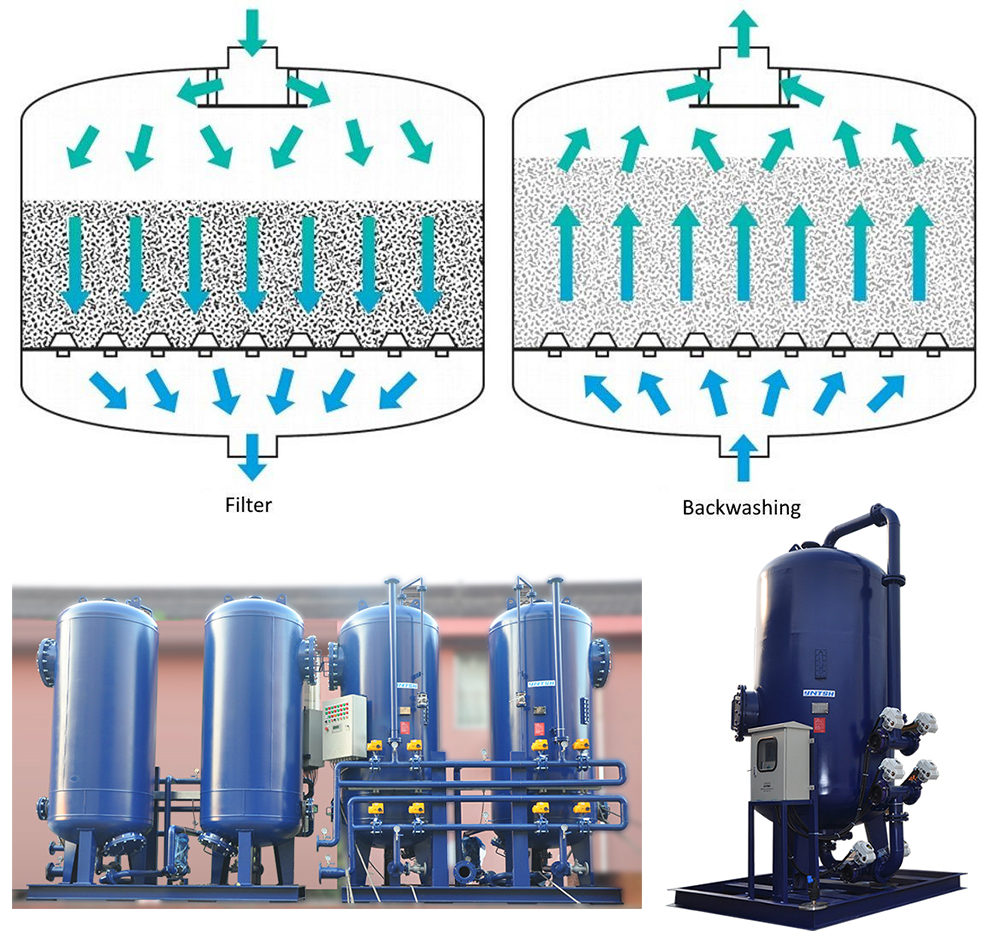

The Principle of Filtration

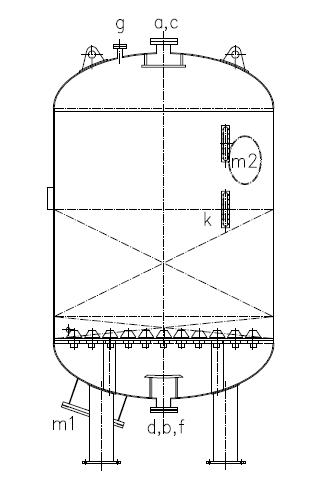

Medium filter is usually called depth filters, water flows through a certain thickness, a certain particle dielectric layer size then reaches the filtering effect. The media may be quartz sand, gravel or granular materials other filtering medium grade depends on the particle diameter and flow through the filter bed velocity, INOCO provides a series of various forms of such products, all kinds of filter media (sand, quartz sand, activated carbon, multilayer media) and accessories, can also provide control system using single or multiple parallel situation.

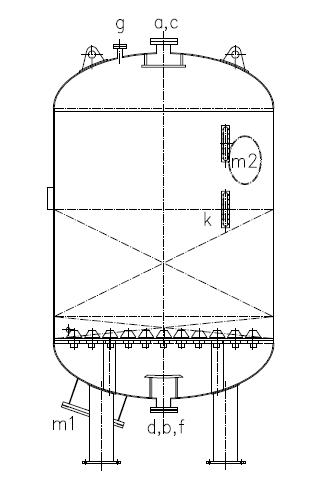

How Media Filters Work

The water flows into the water inlet of the filter and flows through the filter layer, suspended impurities in water by filtering layer adsorption, filtered water from filtering cap flows to the outlet. Filter cleaning can be done by backwashing, the flow is the reverse flow from the water filtering cap upward, causing turbulence filter layer disturbance, the adsorption of impurities is released and discharged through the discharge valve, backwashing process is completed automatically by the inlet and outlet pressure differential or setting time.

▍Sand Filter

Technical Parameters

|

Item

|

16"

|

20"

|

24"

|

30"

|

36"

|

42"

|

|

Body Dia (mm)

|

400

|

500

|

600

|

750

|

900

|

1050

|

|

Inlet/Outlet Dia(mm)

|

40mm; 1 1/2"

|

50mm; 2"

|

50mm; 2"

|

80mm; 3"

|

80mm; 3"

|

80mm; 3"

|

|

Inlet/Outlet Connection Type

|

Thread

|

Thread

|

Thread

|

Flange

/quick joint

|

Flange

/quick joint

|

Flange

/quick joint

|

|

Flow Rate (m³/h)

|

6-10

|

10-18

|

15-25

|

15-35

|

30-50

|

45-65

|

|

Sand Bed Thickness (mm)

|

500

|

500

|

500

|

500

|

500

|

370

|

|

Sand Bed Volume (L)

|

65

|

100

|

140

|

220

|

318

|

320

|

|

Sand Bed Weight (kg)

|

96

|

150

|

210

|

330

|

450

|

480

|

|

Empty Vessel Weight (kg)

|

55

|

75

|

95

|

155

|

200

|

245

|

|

Vessel Volume (L)

|

90

|

150

|

275

|

372

|

535

|

716

|

|

Standard configuration table

|

|

Serial No.

|

main parts name

|

specification

|

|

1

|

Vessel body

|

304,316L, carbon steel lined with rubber…

|

|

2

|

sealing

|

Nitrile rubber, Viton, PTFE

|

|

3

|

Media material

|

Quartz sand, anthracite, magnetite, manganese sand, etc.

|

|

4

|

Manual control

|

manual valve group

|

Inlet Manual Butterfly Valve PN1.0

Water outlet manual butterfly valve PN1.0

Backwash manual inlet butterfly valve PN1.0

Backwash manual discharge butterfly valve PN1.0

Positive washing manual discharge butterfly valve PN1.0

Exhaust valve PN1.0

|

|

5

|

Automatic control

|

automatic valve group

|

Inlet Electric Butterfly Valve PN1.0

Water outlet electric butterfly valve PN1.0

Backwash into electric butterfly valve PN1.0

Backwash electric butterfly valve PN1.0

Positive washing and discharging electric butterfly valve PN1.0

Exhaust valve PN1.0

|

|

6

|

pressure gauge

|

0-0.6MPa

|

|

7

|

Inlet flow meter

|

With signal or rotameter

|

▍Multimedia Filter

Multi-media filter is a process in which one or several filter media are used to pass water with high turbidity through a certain thickness of granular or non-granular materials under a certain pressure, thereby effectively removing suspended impurities and clarifying the water. The filter materials include quartz sand, anthracite, manganese sand, etc., which are mainly used for water treatment to remove turbidity, soften water, pre-treatment of pure water, etc. The turbidity of the effluent can reach below 3 degrees.

Technical Parameter

|

Body Dia

|

|

600

|

800

|

1000

|

1200

|

1400

|

1600

|

1800

|

2000

|

2200

|

2400

|

2600

|

2800

|

3000

|

3200

|

|

Design Flow Rate m/h

|

single-layer media

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

8

|

|

double-layer media

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

10

|

|

Design Flow Capacity m³/h

|

single-layer media

|

2.5

|

4

|

6.5

|

9

|

12.5

|

16

|

20.5

|

25

|

30.5

|

36

|

42.5

|

49

|

56.5

|

64.5

|

|

double-layer media

|

3

|

5

|

8

|

11.5

|

15

|

20

|

25

|

31.5

|

38

|

45

|

53

|

61.5

|

70

|

80

|

|

Shell Thickness mm

|

6

|

6

|

8

|

8

|

8

|

8

|

8

|

10

|

10

|

10

|

10

|

10

|

12

|

12

|

|

Quartz Sand Filter

|

Quartz Sand Filter Media Weight (T)Height (mm)

|

0.5

1000

|

0.9

1000

|

1.7

1200

|

2.4

1200

|

3.3

1200

|

4.3

1200

|

5.4

1200

|

6.6

1200

|

8

1200

|

9.5

1200

|

11.2

1200

|

13

1200

|

14.8

1200

|

16.8

1200

|

|

Manganese Sand Filter

|

Manganese Sand Filter Media Weight (T)Height (mm)

|

0.7

1000

|

1.2

1000

|

2.2

1200

|

3.2

1200

|

4.3

1200

|

5.5

1200

|

7.0

1200

|

8.7

1200

|

10.5

1200

|

12.5

1200

|

14.7

1200

|

17

1200

|

19.5

1200

|

22.2

1200

|

|

Multi-media Filter

|

Quartz Sand Filter Media Weight (T)Height (mm)

|

0.3

600

|

0.6

600

|

1.1

800

|

1.6

800

|

2.2

800

|

2.9

800

|

3.6

800

|

4.4

800

|

5.4

800

|

6.4

800

|

7.5

800

|

8.6

800

|

9.9

800

|

11.3

800

|

|

Anthracite Filter Media Weight (T)Height (mm)

|

0.1

400

|

0.2

400

|

0.3

400

|

0.4

400

|

0.6

400

|

0.8

400

|

1.0

400

|

1.2

400

|

1.45

400

|

1.7

400

|

2.0

400

|

2.4

400

|

2.7

400

|

3.0

400

|

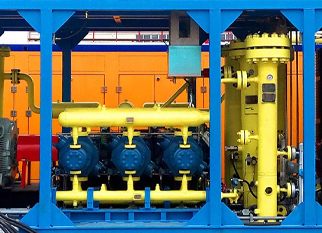

▍Fully Automatic Shallow Sand Filter

The fully automatic shallow filtration system is composed of multiple standard high-speed sand tank units, with a unique water distributor and water collector inside, and a unique two-way automatic flush valve, which can realize multiple standard high-speed in normal system operation. The sand tank is backwashed individually one by one, fully automatic program control. It has the advantages of small backwash water consumption, convenient equipment installation and easy operation. The device has a high flow rate and requires no maintenance. According to different user requirements, there are vertical and horizontal two series. It is suitable for water quality treatment of industrial and civil circulating water systems.

Working Principle

Washing filter status:

When the system is in the filtering state, the unfiltered water is evenly distributed through the self-developed unique water distributor, and the water passes through the packing layer (refined uniform-grained quartz sand/garnet) in the filter in a laminar flow state. When water flows through the packing layer, impurities are trapped in the packing layer. There is a plurality of evenly distributed water collectors at the bottom of the filter, the filtered water is evenly collected and drawn out, and the advective filtration can make the filter at a high flow rate, and still achieve a better filtering effect. Backwash state: As impurities accumulate in the packing layer, the internal head loss will continue to increase. When the head loss of the inlet and outlet water reaches the set value, the system will automatically activate the constant pressure device to switch to the backwashing state. When the backwashing is over, the hydraulic valve changes the direction of the water supply to realize the backwashing one by one, which is more convenient Clean up accumulated impurities. When the system is in the state of backwashing, the filtration continues, the standard unit sand tank to be backwashed is not filtered, and the other standard unit sand tanks in the system are still filtering. Part of the filtered clean water is used to backwash the standard unit sand tank, and the rest is still sent to the user. The backwash sewage is discharged through the backwash drain of the hydraulic valve. In the automatic high-efficiency filtration system of the high-speed sand tank, the special water collector design can make the fillers rub each other, maximize the backwashing efficiency, reduce the required backwashing water (clean water), and at the same time when backwashing No runaway phenomenon. A standard unit sand tank is backwashed for 2 minutes. After the backwash is completed, the internal pressure head loss of the standard unit sand tank is reduced to a reasonable range. The constant pressure device gives a recovery signal, and the hydraulic valve returns to the filtering state. The next standard unit sand tank Then prepare to enter the backwash state product features.

Features:

1. Small size, easy installation and space saving. It can be installed outdoors, no need to build a house, save the cost of civil construction, occupy a very small area, can be installed indoors and outdoors, and can also be installed in layers from top to bottom, with strong adaptability; automatic shallow sand filter.

·Compact structure and space saving ·The product has good anti-corrosion performance and can be installed indoors and outdoors.

2. The equipment has good anti-corrosion performance and long service life.

3. Large amount of filtration water, good filtration effect, fast filtration flow rate, normal filtration rate can be about 40m/h, according to water quality up to 60m/h; filter backwash adopts product water, and no booster pump and backwash pump are required; Backwashing lasted 2-3min, backwashing water volume <3m3. ·High filtration precision, impurity filtration precision can be below 0.10mm, effluent turbidity can be less than 0.5NTU. The filtration system consists of a standard unit sand tank, and the filtration flow can be increased from 30.6 cubic meters per hour to 2500 cubic meters per hour.

4. Automatic backwashing: The backwashing of the equipment is automatically identified and controlled by the intelligent control system without manual intervention. Even if the suspended matter in the water fluctuates, the equipment may automatically adapt.

5. The water supply is uninterrupted; when the equipment is backwashed, the filtration process is carried out at the same time, and the system supplies water as usual.

6. Adopt unique cloth and water collection device. Because of the unique water distribution system of the filtration system and the very evenly distributed water collector, the water flow is layered in the whole filtration process, and the plane of the filter sand bed is always flat during the filtration process, and the water is discharged. Water quality is stable.

7. Use refined and preferred quartz sand or garnet as the filter medium. Select according to the water quality. The minimum particle size of the filter material can be a homogeneous filter material of 0.16mm.

8. The long-term operation cost is low, saving electricity, water and maintenance costs. Power saving: The system has a unique automatic backwash valve. The sand filter tank is not backwashed at the same time, but is backwashed one by one under the normal operation of the system, and there is no need to consider setting a backwash pump. At the same time, compared with other sand filter equipment, the required lift of the filter pump is 6-7m lower. Water saving: Because of its unique water replenisher and water collector, the system has a unified tank body, so that the medium layer can be very uniformly expanded for effective backwashing without the need for compressed air during backwashing. The water used for backwashing is filtered clean water, so the consumption of backwashing water is small. Backwash water volume per tank Fully automatic shallow sand filter.

Only 1m3/min, the backwash time is 2-3 minutes. Save maintenance costs: The whole system has no mechanical or electric valves, and only relies on a unique multi-function valve to control the backwashing of the system. Due to the unique multi-function valve has no wear and long life, there is no damage record within 10 years, and the management cost is low.

Applications:

1. Filtration of industrial water --- There are certain system requirements for water quality. Such as: steel mill oxygen lance water, boiler, heat exchanger water supply filtration, etc., can filter out impurities in the water and avoid the blockage of several nozzles in the pipeline.

2. Filtration system for industrial circulating water.

3. Raw water treatment --- It can filter surface river water, lake water, sea water, reservoir water, well water and urban tap water as the water source for urban districts' differentiated water supply, etc., to remove sand particles, suspended solids, algae, organic matter, etc. in the water.

4. Agricultural irrigation---especially suitable for water sources with high flow and good impurity content, such as irrigation of farmland, irrigation of lawns in parks and golf courses, etc.

5. Water for food processing industry, papermaking industry, treatment of industrial circulating water in power plants, etc., pretreatment of industrial and medical purified water. Recycling of industrial production water, industrial wastewater treatment.

6. Aquaculture, swimming and water park industries.

7. Landscape circulating water.

8. It is used for industrial water, domestic water and municipal water supply systems that require effluent turbidity ≤5mg/L to meet drinking water quality standards;

9. Removal of suspended solids and solids in industrial sewage;

10. It can be used as pretreatment equipment in ion exchange softening and desalination systems, and coarse filtration equipment for industrial water supply that does not require high water quality;

And used in swimming pool circulation treatment system, cooling circulating water purification system, etc.

INOCO Green Energy Solutions Co., Ltd. |