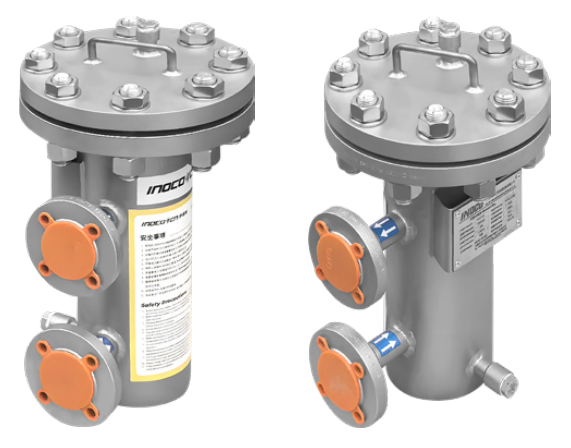

▍Carbon Steel and Anticorrosive Basket Filter

INOCO-SBL-C Series

In order to cope with the influence of ocean humidity on the outside of the shell, we have developed vinyl-ester glass flake lining with tensile strength up to 10MPa. To address the impact of marine humidity on the exterior of the shell, in addition to selecting suitable paint, INOCO performs CPT reports for all painting procedures. Furthermore, paint inspectors are certified with NACE (CIP) Coating Inspector Level II or above.

Seawater-resistant painting process: Plasite 4550S Part A + Plasite 4550S Part B (Carboline).

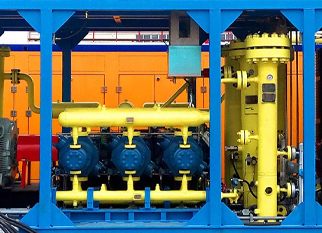

Marine Filter

As ship owners and operators increasingly demand to reduce pollutants while improving efficiency, the maritime industry faces multiple challenges. INOCO offers a range of innovative, high-performance filtration products that meet all offshore requirements. To date, we have cumulatively supplied over a hundred sets of filters to CNOOC, BP, Petrobras, Petronas, Fluor, Technip, and YINSON.

We are continuously strengthening and improving our global supply chain system. To comply with global quality standards, INOCO factory has passed certifications such as Bureau Veritas (France) factory certification, TUV (Germany) factory certification, ASME U Stamp (USA), EU PED, Russia CUTR, and China TS Pressure Vessel.

Global Quality Standards

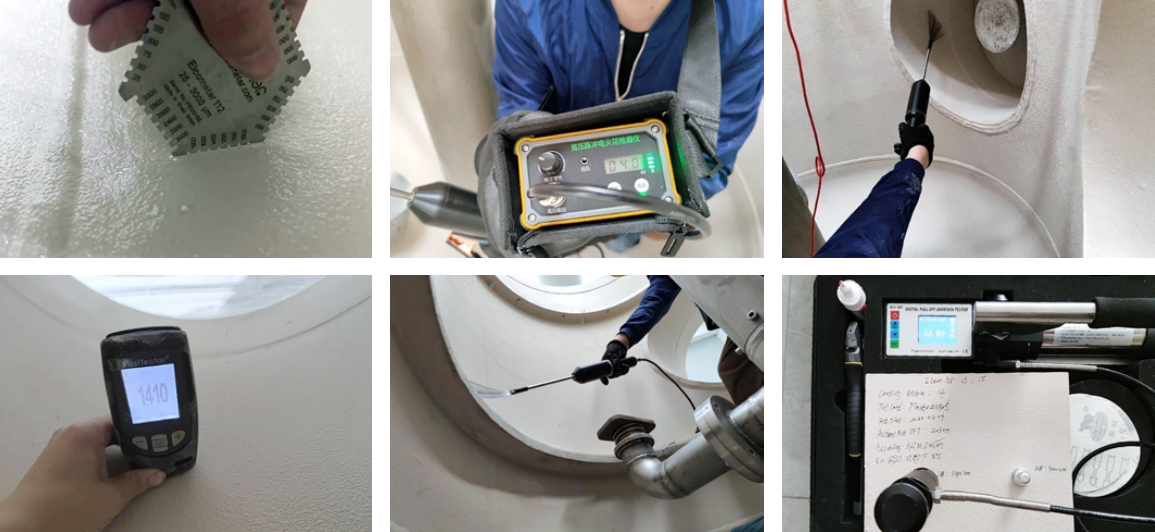

INOCO SERVICES

INOCO provides services such as PQP (ISO 10000), ITP, General Arrangement and Construction Drawings, 3D MODEL, POR, WPS, Performance Guarantee (Strength and Pressure Drop Calculation, Load Calculation and Fatigue Analysis, Flow Analysis), PMI, Corrosion, Metallography, Torque, Low Temperature Impact, Ferrite Control, Welding Deformation Control, Electrical Instrumentation (Electrical Schematic Diagram, Motor Perfor�mance Curves and Data Sheet, Instrument Connection Logic Diagram, Terminal Block Diagram, Cylinder Torque Calculation, Safety Valve Calculation Sheet), FAT, Redundancy Assurance, HSSE Management, NDE Proce�dures, Painting Procedures, Packaging and Transportation Solutions, Installation and Maintenance Manual, etc.

Technical Parameters

Shell Material:

Carbon Steel, 304, 316L, 2205, 2507, 904L

Titanium Alloy, Hastelloy

Lined PP, Lined PTFE, Sprayed PTFE

Sealing Ring Material:

NBR (Standard)

Metal Gasket, Graphite Gasket

FKM, Teflon Encapsulated FKM

Filter Element Material:

304 (Standard), 316L, 2205

Maximum Operating Pressure:

1.0MPa (150PSI) (Standard) / 10000PSI (Custom)

Design Temperature Range:

Filter bag and gasket not considered for design temperature

Carbon Steel: -6-250℃

Stainless Steel: -28-298℃

Inlet and Outlet Connection:

Butt welding, Thread, Flange

Surface Treatment:

Carbon Steel: Exterior Sandblasting and Painting

Stainless Steel: Sandblasting (Standard), Pickling, Polishing

Stamped Certification:

GB150, TS, ASME U or UM Stamp

EAC, CE, Classification Society Certification

Opening Method:

Standard Bolts, Quick Release Bolts,Quick Opening Blind Flange/Closure

INOCO ADVANTAGES

☑ Multi-filter element structure

☑ Folding filter element

☑ Filter element sealed with O-rings

☑ Internal lining uses seawater-resistant anticorrosive coating

☑ Easy-to-use and secure quick-closing device

☑ Electropolished perforated filter basket

☑ Pickling and degreasing

☑ Flange management

☑ Ferrite control

INOCO CAPABILITIES

Design Capabilities

☑ Pressure Drop Curve

☑ Finite Element Analysis

☑ Flow Analysis

☑ Flow and Pressure Drop Simulation

☑ Seismic Analysis

☑ Loading Rate

☑ Skid Modeling

Manufacturing Capabilities

International Quality System Certification, Global Classification Society Factory Certification, International Welding Engineer, International Welder, International NDE Level III Qualification, US NACE (CIP) Level II Qualification.

INOCO PRODUCTS

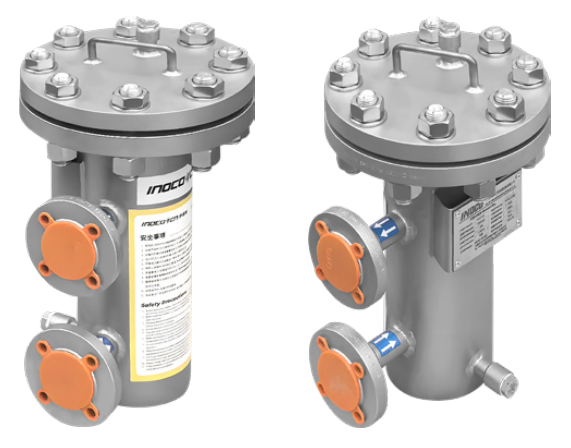

▍Ultra-High Pressure Basket Filter

INOCO-SBL-H Series

INOCO-SBL-H series is specially developed for ultra-high pressure working conditions, with a working pressure reaching 10000PSI.

Product Advantages

|

Factory certified by BV for ultra-high pressure

|

|

Management of super duplex materials

NORSOK M650 Certification

|

|

Ferrite Control

|

|

Extreme -52℃ Low

Temperature Impact Resistance

ISO Standard: -46℃

National Mandatory Standard: -40℃

|

▍Basket Filter for Nuclear Power

INOCO-SBL-HI Series

INOCO strictly complies with nuclear power plant regulations RCC-M standard system

Filters can be helium tested as required

Whether in demanding nuclear power plants or nuclear contamination treatment stations, INOCO can select from a range of filtration, separation, and purification systems based on customer-specific needs, helping customers reduce costs, minimize radioactive exposure, and comply with strict regulatory requirements.

▍Insulated Basket Filter

INOCO-SBL-M Series

Designed and manufactured by INOCO to meet the need for insulation during fluid filtration to achieve good conveying performance, or based on user working conditions, to overcome media that easily crystallize or solidify due to temperature drop. It features a welded insulation jacket on the basic basket filter, used to inject steam or heat transfer oil to maintain or raise the fluid temperature, prevent material solidification, improve the filtration speed of viscous liquids, or meet the temperature requirements of the next process. This product is particularly suitable for filtering media in low-temperature environments or those with high viscosity, and is widely used in various systems in the Petroleum, Chemical, Asphalt, Metallurgy, Pharmaceutical, Food industries.

▍Quick Opening Blind Flange Basket Filter

INOCO-SBL-K Series

The Quick Opening Blind Flange Basket Filter is a vertical, straight-through quick-opening filter with a quick opening blind flange welded onto the shell, enabling rapid opening, closing, and sealed locking, and featuring a safety interlock function. Its quick opening blind flange can be designed in various structural forms as needed, such as lever quick opening, lifting ring quick opening, cantilever lifting ring quick opening, and clamp quick opening. When removing the filter element, it does not require multiple operators or lifting equipment; simply open the top cover using the quick opening blind flange mechanism and remove the filter basket for cleaning, saving time and effort.

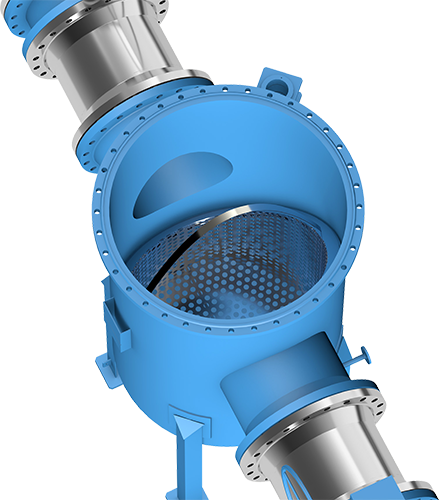

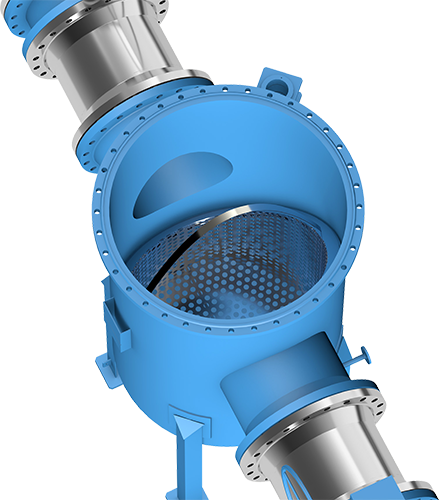

▍Extra Large Basket Filter

INOCO-SBL-B Series

Extra Large Basket Filters are critical large-flow filtration equipment in industrial pipeline systems. They intercept solid particles (such as welding slag, rust, fibers, etc.) in liquids using a high-strength metal filter basket, protecting downstream equipment such as pumps, valves, and heat exchangers. Suitable for high-pressure, high-flow, and corrosive conditions, they are the preferred filtration solution in the energy, chemical, and water treatment fields.

▍Electropolished Basket Filter

INOCO-SBL-SP Series

To meet the strict filtration requirements for surface finish, corrosion resistance, and microbial control in demanding fields (such as biopharmaceutical, food and beverage, and semiconductor industries), INOCO offers Electropolished Basket Filters. This type of filter is precision filtration equipment treated with electrochemical polishing. Its inner surface roughness can reach Ra ≤ 0.4um, significantly reducing the risk of particle adhesion and bacterial growth.

▍T-type Filter

INOCO-ST Series

T-type filters are devices used to remove solid impurities during liquid pipeline transportation. When the liquid flows through the filter, impurities are filtered out, protecting pumps, compressors, instruments, and other equipment from normal operation. When cleaning is required, the removable filter element can simply be taken out, cleaned, and reinstalled, making operation and maintenance extremely convenient.

Widely used in fields such as Petroleum Chemical, Water Treatment Systems, HVAC Systems, Food and Beverage Processing, Pharmaceutical, and Industrial Manufacturing.

▍High Pressure Y-type Filter

INOCO-SBY-H Series

High-pressure Y-type filters are indispensable "guardians" in high-pressure fluid systems.

With their robust structure, excellent pressure resistance, strong dirt-holding capacity, and relatively easy maintenance, they provide reliable protection for expensive, critical equipment in harsh industrial environments and are a crucial component in ensuring the long-term, safe, and stable operation of the entire system.

▍Ultra-High Pressure Temporary Filter

INOCO-SV Series

Designed by INOCO to meet short-term high-pressure conditions (such as system debugging, equipment startup, maintenance), the removable Ultra-High Pressure Temporary Filter can temporarily intercept particles at pressures of 42~100MPa or even higher, protecting critical equipment from contamina�tion. Its core features are quick assembly/dis�assembly, extreme pressure bearing capacity, and precise interception, widely used in high-end fields such as Energy, Military, and Chemical industries.

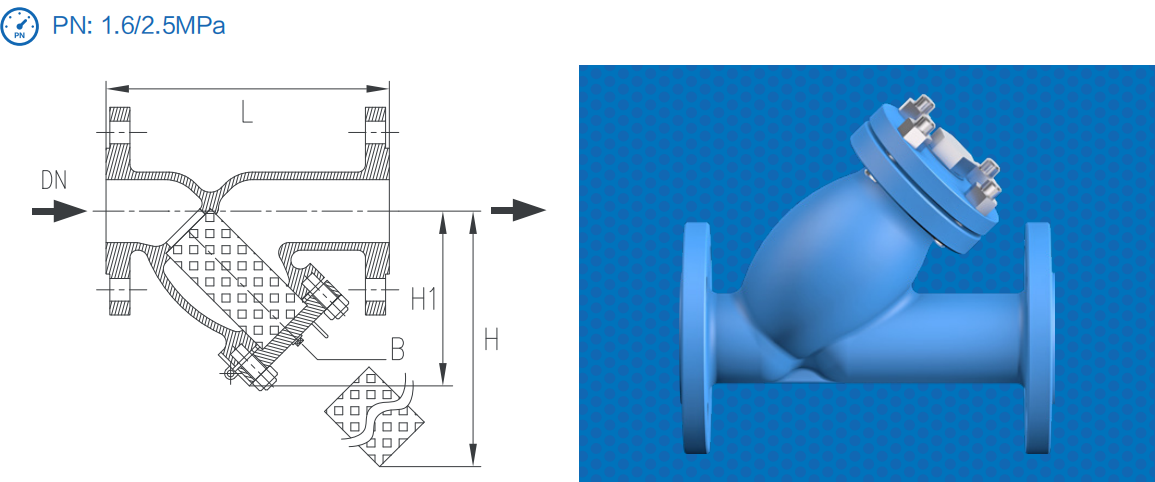

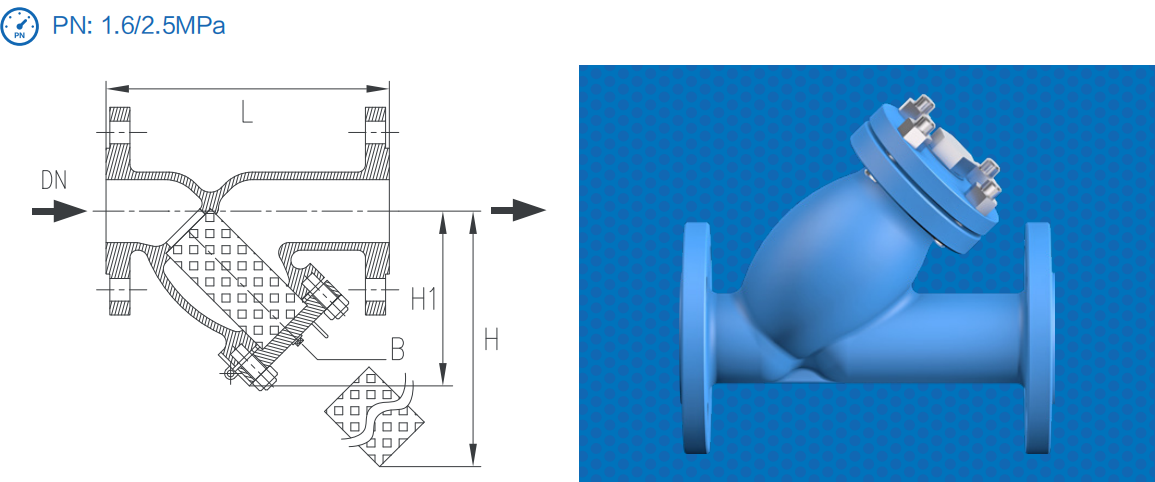

▍Same Diameter Cast Y-type Filter

SRY I Series

Specifications and Dimensions

|

Nominal Diameter (DN)

|

Dimension (mm)

|

Reference Weight (kg)

|

Effective Filtration Area (m2)

|

Multiple

|

|

L

|

H1

|

H

|

B

|

|

*15

|

150

|

119

|

167

|

R1/2

|

4.9

|

0.0009

|

5.0

|

|

*20

|

150

|

119

|

167

|

R1/2

|

5.4

|

0.0009

|

3.0

|

|

*25

|

150

|

119

|

167

|

R1/2

|

5.9

|

0.0009

|

1.8

|

|

*(32)

|

170

|

150

|

209

|

R1/2

|

6.3

|

0.00175

|

2.0

|

|

*40

|

170

|

150

|

209

|

R1/2

|

7.1

|

0.00352

|

2.8

|

|

50

|

280

|

180

|

335

|

R1/2

|

11.2

|

0.00515

|

2.6

|

|

80

|

360

|

250

|

436

|

R3/4

|

32.2

|

0.011

|

2.2

|

|

100

|

380

|

280

|

540

|

R3/4

|

48.9

|

0.014

|

1.8

|

|

150

|

520

|

360

|

710

|

R3/4

|

99.0

|

0.032

|

1.8

|

|

200

|

660

|

450

|

890

|

R3/4

|

152.7

|

0.056

|

1.8

|

|

250

|

850

|

665

|

1240

|

R3/4

|

216.6

|

0.0883

|

1.8

|

1. Angle for items with * is 55°(others are 45°);

2. Effective filtration area is calculated based on 30 mesh screen. Same for all tables in this chapter;

3. Reference weight is for PN2.5 level.

INOCO Green Energy Solutions Co., Ltd. |