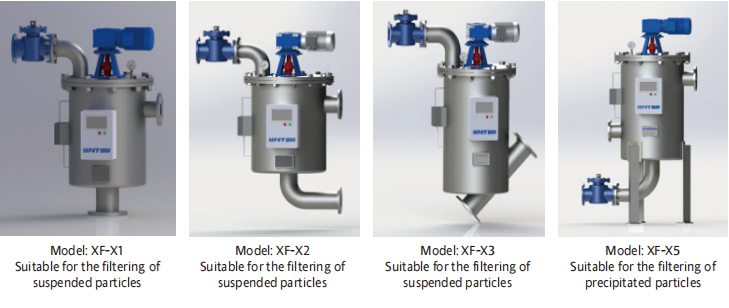

▍INOCO-XF-X SERIES SELF-CLEANING FILTER SERIES

INOCO XF-X series self-cleaning filter is suitable for DN25~DN900 pipelines.

The filter has the advantages of continuous fluid flow, easy maintenance and

reliable operation, so it is widely used in all industries.

INOCO-XF-X series is a type of fully automatic self-cleaning filter suitable

for harsh environments. For different operation requirements, it can be

equipped with 3500µm~50µm filter sieve with a caliber of 8” ~36” . The

self-cleaning process of INOCO filter is started by a pressure difference

switch that constantly monitors the pressure difference between the inlet and outlet of the filter. Usually, the

preset value of the pressure difference switch is 0.5bar (7psi).

▍INOCO-XF-X SERIES SELF-CLEANING FILTER SERIES

Features and Advantages

■ Uninterrupted water supply: The water quantity is very little during

cleaning, which is 5% of the water output of the filter, and the washing time

is 2-15s. The entire system supplies water uninterruptedly.

■ High filtering precision: The filtering precision can reach up to 20µm, and

there are filter sieves of various precision for your selection.

■ Large filtering area: The effective filtering area of standard filter sieve

is 7-40 times the area of the inlet.

■ Reliable cleaning: There are various control modes, such as manual, pressure

difference, time and PLC, etc.

■ Economical and simple installation: There are various structure forms, which

are suitable for installation in various situations on the site without

affecting the operation effect.

■ Long service life: The service life is more than 10 years under normal

conditions, and the material of filter sieve is stainless steel. According to

requirements, filter sieves of different specifications can be easily replaced

as required.

General Parameters

■ Operating flow rate: 20~5000m3/h (please contact the manufacturer for

details, the corresponding flow rate is different for different water quality

& precision)

■ Minimum working pressure: 2Kg. If the working pressure is too low, booster

pump can be installed at the sewage outlet.

■ Maximum working pressure: 10Kg; 150psi. High-pressure type can be customized

according to user requirements, please contact the manufacturer for details.

■ Filtering area: 3000cm2 ~20000 cm²

■ Inlet / outlet diameter: 50, 80, 100, 150, 200, 250, 300, 350, 400, 500, 600,

800mm Maximum working temperature: 50°C.

■ Please give special description if higher than this temperature.

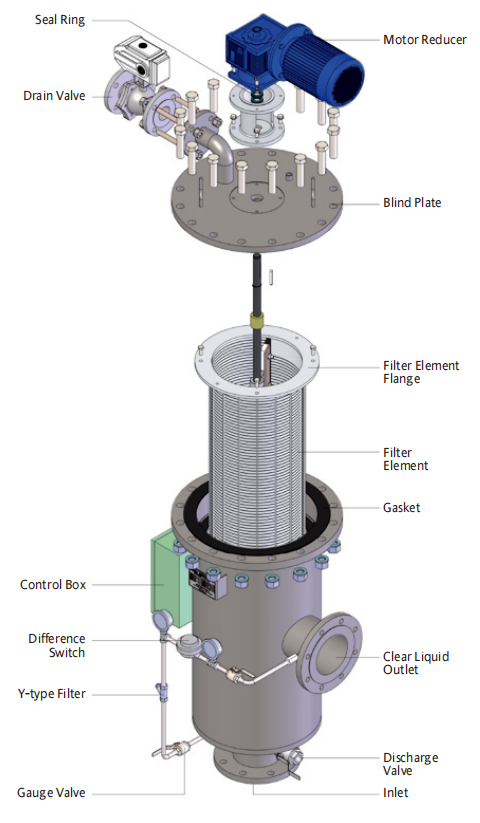

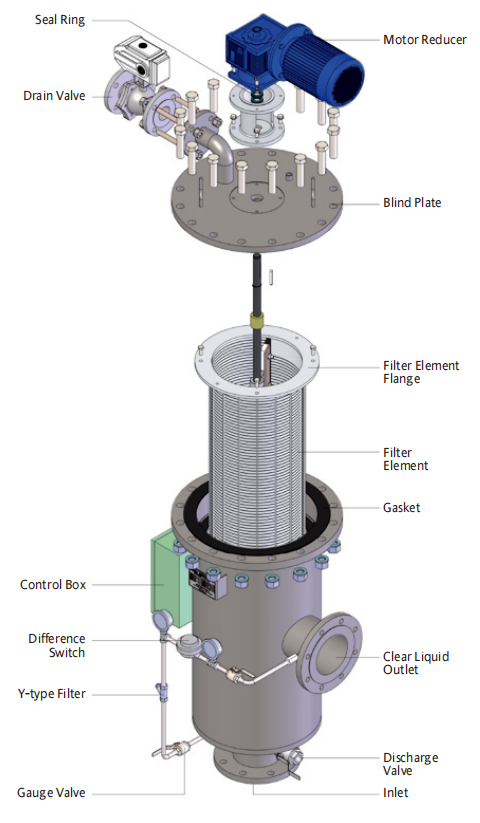

Filter Working Principle

When the pressure difference between the inlet and outlet of the filter

reaches the preset value, the filter will start the self-cleaning process. The

entire self-cleaning process includes two steps: open the drain valve on the

upper end cap of the filter; the motor drives the two stainless steel brushes

in the filter sieve to turn, and the impurities captured by the filter sieve

are brushed off by the steel brushes and discharged from the drain valve. The

entire cleaning process takes about 15-60s. There is uninterrupted water

supply in the system during cleaning. The entire operating process of the

filter is controlled by a control box provided for the filter.

Cleaning Parameters

◎ Size of drain valve: 25mm; 50mm; 80mm

◎ Cleaning time: 30-60s

◎ Water consumption per cleaning: ≤5%.

Filter Body and Cap

◎ Filter body: carbon steel, epoxy resin coating.

316 and 304 stainless steel can be used upon request.

◎ Filter sieve: 316L stainless steel wedge-shaped filter element;

316L stainless steel braided steel wire

◎ Cleaning mechanism (interior): stainless steel 304, 316L, POM

◎ Drain valve: cast iron, epoxy resin coating; 304, 316L

◎ Seal ring: synthetic rubber, PTFE

Standard Filter Rating

◎ Precision of braided filter sieve: 500,300, 200,130,100, 80,50,25,10 micron

◎ Precision of wedge-shaped filter element: 50,80,100, 200, 300, 500 micron

Performance Parameters

1. Factory-set cleaning interval time: 4 hours (adjustable)

2. Factory-set cleaning pressure difference: 0.lMPa (adjustable)

3. Input voltage: 380V 3-phase 50HZ

4. Standard working pressure: 0.6MPa

5. Maximum working pressure: 1.0MPa

6. Standard working temperature: 50℃

7. Maximum working temperature: 70℃

8. Cleaning control modes: manual, automatic (time / pressure difference)

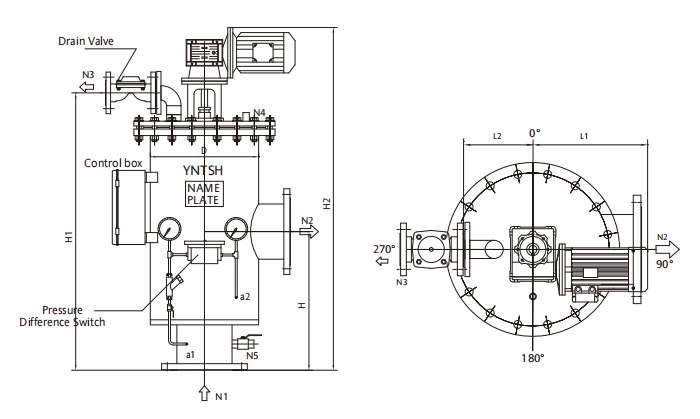

▍INOCO-XF-X SERIES SELF-CLEANING FILTER SERIES

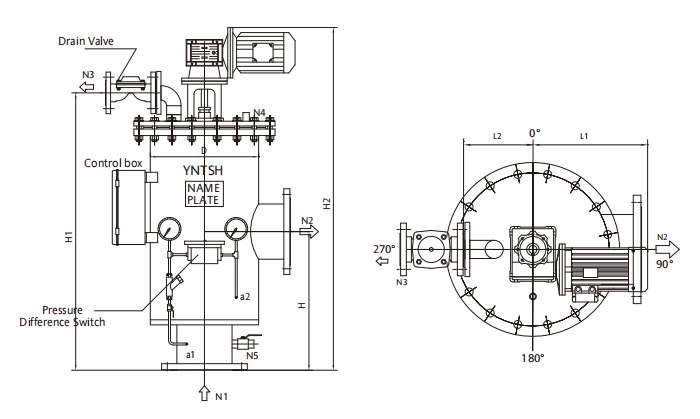

Product Parameters and Sizes

|

Model

|

X1-219

|

X1-273

|

X1-325

|

X1-426

|

X1-530

|

|

Pipe dia.(mm)

|

80

|

100

|

125

|

150

|

200

|

|

Filtering flow rate (m3h)

|

50

|

80

|

130

|

190

|

330

|

|

Filtering area (m2)

|

0.27

|

0.34

|

0.41

|

0.66

|

0.88

|

|

Drain valve (mm)

|

25

|

25

|

25

|

50

|

50

|

|

Water consumption

|

60

|

60

|

60

|

250

|

250

|

|

per cleaning (L)Motor power (KW)

|

0.55

|

0.55

|

0.55

|

0.55

|

0.55

|

|

Model

|

X1-219

|

X1-273

|

X1-325

|

X1-426

|

X1-530

|

|

D(mm)

|

219

|

273

|

325

|

426

|

530

|

|

H(mm)

|

500

|

500

|

500

|

600

|

600

|

|

H1(mm)

|

830

|

830

|

980

|

1160

|

1190

|

|

H2(mm)

|

1130

|

1130

|

1200

|

1350

|

1380

|

|

L1(mm)

|

210

|

235

|

350

|

350

|

400

|

|

L2(mm)

|

180

|

200

|

300

|

300

|

360

|

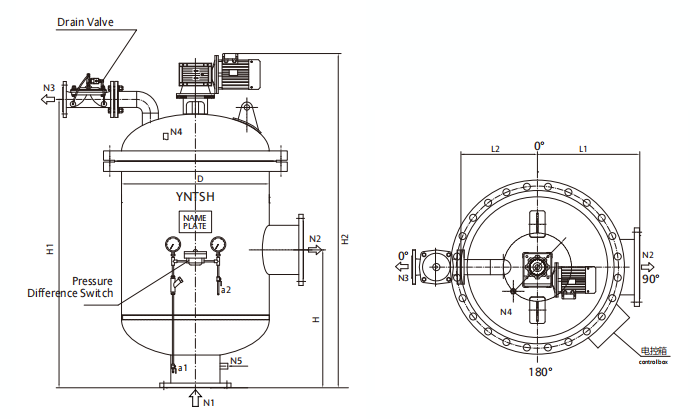

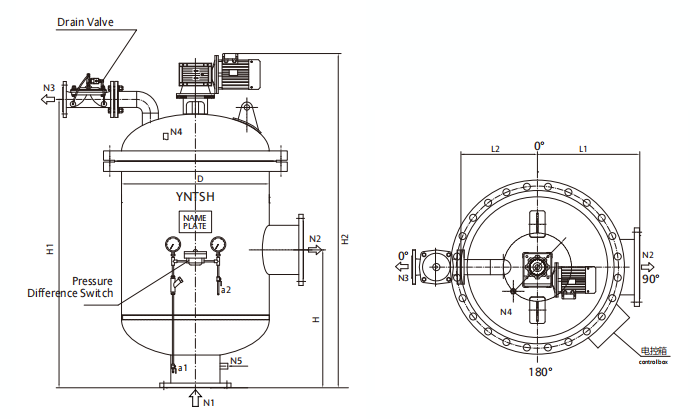

Product Parameters and Sizes

|

Model

|

X1-630

|

X1-720

|

X1-820

|

X1-920

|

X1-1020

|

|

Model

|

250

|

300

|

350

|

400

|

450

|

|

Filtering flow rate (m³/h)

|

530

|

750

|

1000

|

1350

|

1700

|

|

Filtering area (㎡)

|

1.1

|

1.9

|

2.2

|

2.6/3.1

|

3.5/4.0

|

|

Drain valve (mm)

|

80

|

80

|

80

|

80

|

80

|

|

Water consumption per cleaning (L)

|

350

|

450

|

600

|

800

|

1000

|

|

Motor power (KW)

|

0.75

|

0.75

|

0.75

|

0.75

|

0.75

|

|

Model

|

X1-630

|

X1-720

|

X1-820

|

X1-920

|

X1-1020

|

|

D(mm)

|

630

|

720

|

820

|

920

|

1020

|

|

H(mm)

|

750

|

900

|

900

|

1000

|

1100

|

|

H1(mm)

|

1450

|

1820

|

1900

|

2070

|

2350

|

|

H2(mm)

|

1670

|

2030

|

2130

|

2280

|

2580

|

|

L1(mm)

|

450

|

500

|

600

|

650

|

700

|

|

L2(mm)

|

400

|

400

|

450

|

500

|

600

|

Performance Parameters

1. The filtering flow rate is the theoretically maximum flow rate that the

filter element can reach, calculated according to the precision of l00um.

2. Factory-set cleaning interval time: 4 hours (adjustable)

3. Factory-set cleaning pressure difference: 0.lMPa (adjustable)

4. Input voltage: 380V 3-phase 50HZ

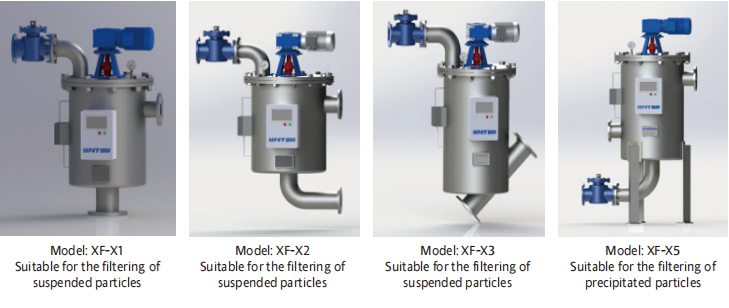

Product parameters and sizes

|

No.

|

Model

|

Self-cleaning Filter

|

No.

|

Material of Filter Gasket

|

|

1

|

XF-X1

|

Filtering of suspended particle

|

★

|

19

|

N

|

Butyronitrile

|

★

|

|

2

|

XF-X5

|

Filtering of precipitated particles

|

|

20

|

E

|

EPDM

|

H

|

|

3

|

50

|

Size of filter inlet and outlet

|

★

|

21

|

F

|

Fluororubber

|

H

|

|

4

|

219

|

Diameter of filter casing

|

★

|

22

|

P

|

PTFE

|

H

|

|

Material of Filter Casing

|

23

|

S

|

Metallic spiral wound gasket

|

H

|

|

5

|

Q2

|

Q235B

|

★

|

|

|

6

|

Q3

|

Q345R

|

H

|

Standard of Filter Flange

|

|

7

|

Q2N

|

Q235B rubber lining

|

H

|

24

|

H16

|

HG20592-09 PN16 PL RF

|

★

|

|

8

|

Q3N

|

Q345R rubber lining

|

H

|

25

|

A20

|

ASME B16.5 150LB SO RF

|

H

|

|

9

|

Q2S40

|

Q235B coated with PTFE

|

H

|

|

|

10

|

S3

|

304

|

★

|

Filter Precision

|

|

11

|

S6

|

316L

|

★

|

26

|

M300 、M200

|

200 、300(micron)

|

★

|

|

12

|

S25

|

2205

|

H

|

27

|

M50

|

50 、100 、150 、400、

|

H

|

|

13

|

S27

|

2507

|

H

|

|

|

500 、1000 、2000(micron)

|

|

Material of Filter Element

|

Automatic Drain Valve

|

|

14

|

E3

|

304

|

★

|

28

|

EBV50

|

Electric valve DN50

|

★

|

|

15

|

E6

|

316L

|

★

|

29

|

PV50

|

Pneumatic valve DN50

|

H

|

|

16

|

E25

|

2205

|

H

|

Explosion-proof Grade

|

|

|

17

|

E27

|

2507

|

H

|

30

|

B4

|

Exib Ⅱ BT4

|

H

|

|

18

|

E2T

|

Titanium

|

H

|

31

|

C4

|

Exib ⅡCT4

|

H

|

|

Degree of Protection

|

|

32

|

I55

|

IP55: Prevent foreign objects and dust;protect against

low-pressure water spray of at least 3 minutes

|

★

|

|

33

|

I56

|

IP56: Prevent foreign objects and dust; protect against

massive water spray of at least 3 minutes

|

H

|

|

34

|

I65

|

IP65: Completely prevent foreign objects and dust from

entering; protect against low-pressure water spray of at least 3 minutes

|

H

|

|

35

|

I66

|

IP66: Completely prevent foreign objects and dust from

entering; protect against massive water spray of at least 3 minutes

|

H

|

|

Material Traceability Certificate

|

|

36

|

G

|

In line with GB

|

★

|

|

37

|

A

|

In line with ASME

|

★

|

|

38

|

E

|

In line with EN 10204 3.1.B

|

H

|

|

Product Certification

|

|

39

|

TS

|

China Steel Pressure Vessels

|

H

|

|

40

|

U2

|

ASME Usteel seal

|

H

|

★ The standard options provided represent the most commonly used options.

The options with an asterisk (★) should be selected for optimal delivery.

H Represents customized options, and the standard products

do not include H options.

If necessary, please describe the requirements in the order.

INOCO Green Energy Solutions Co., Ltd. |